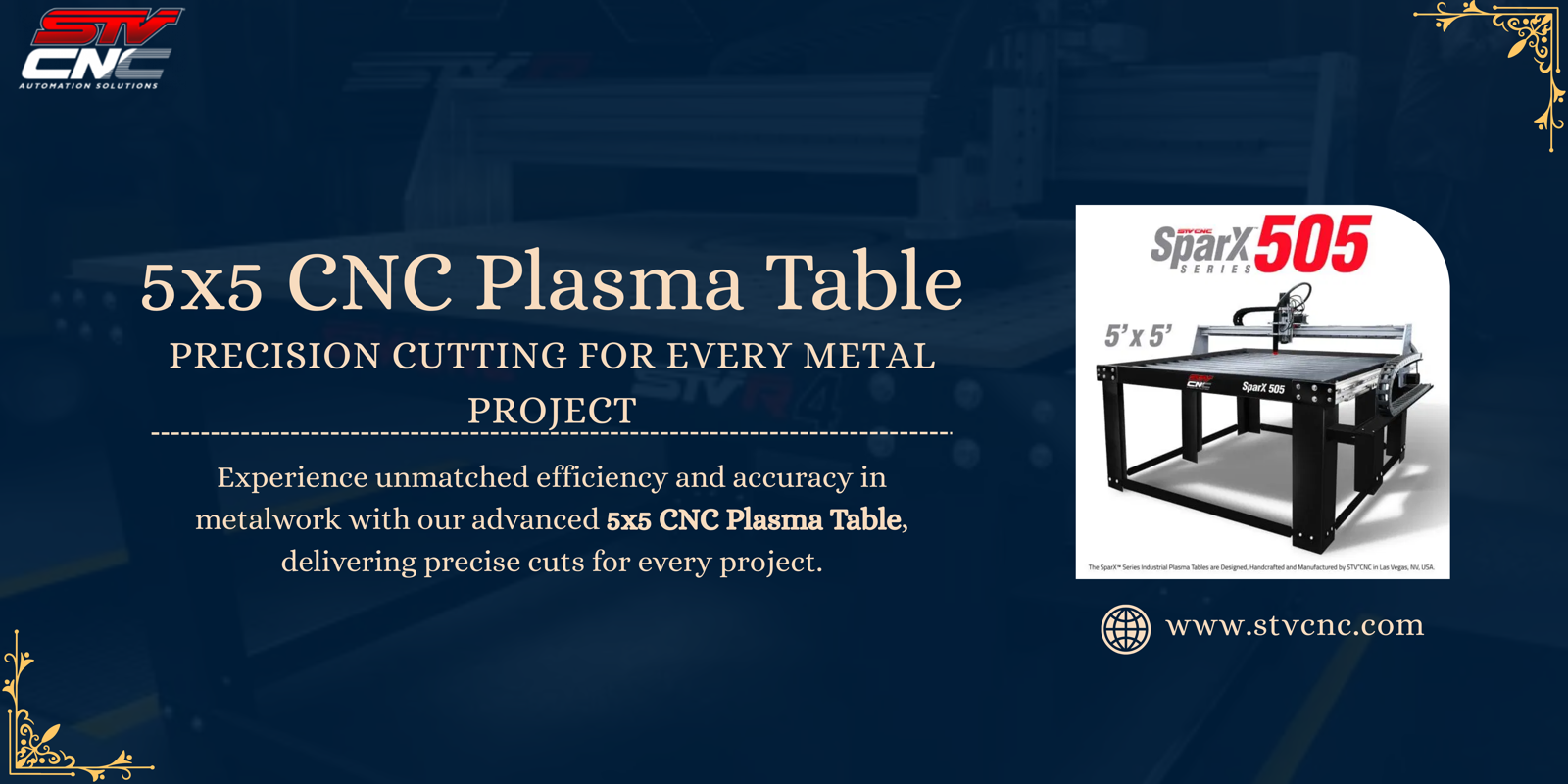

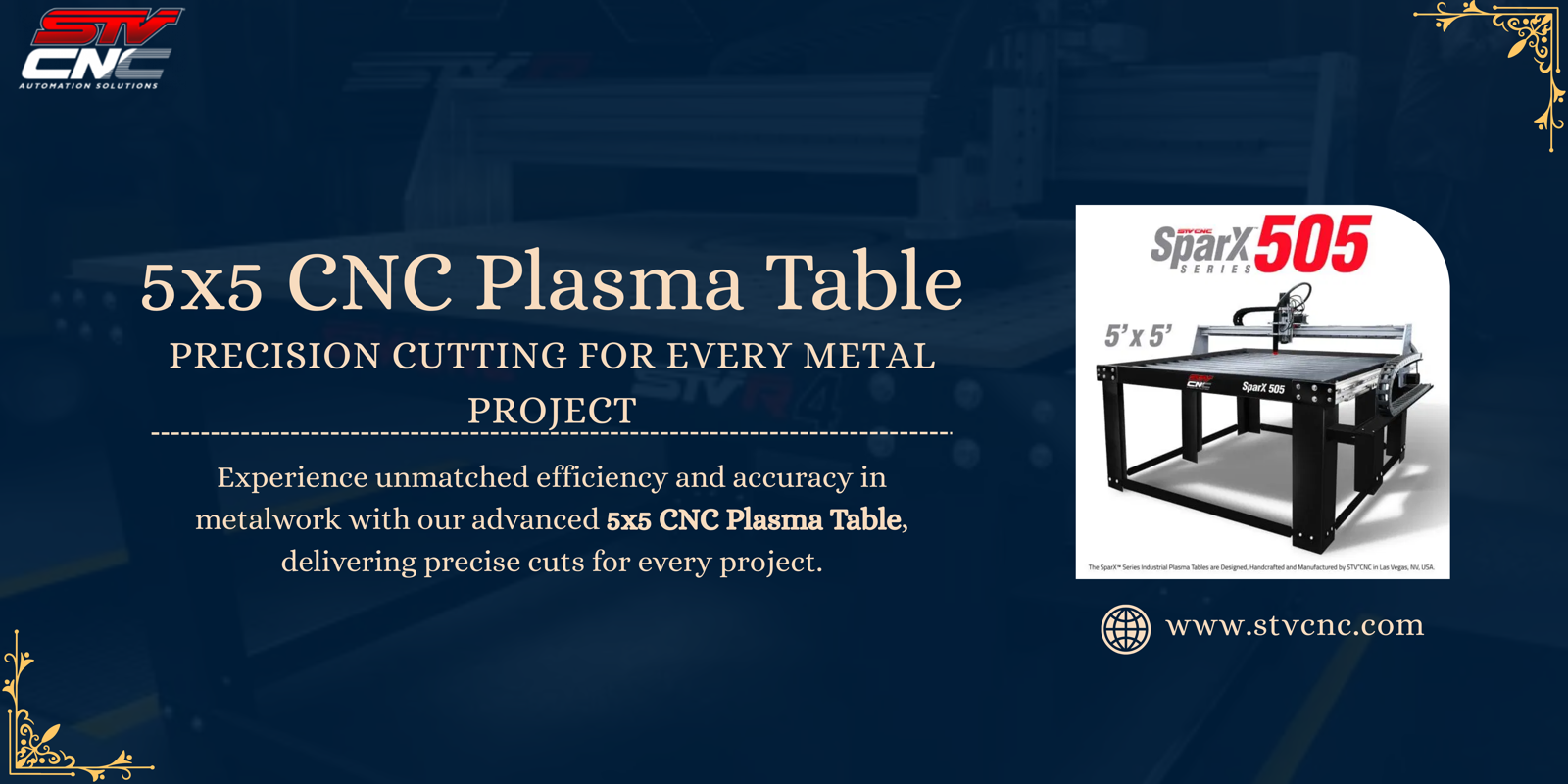

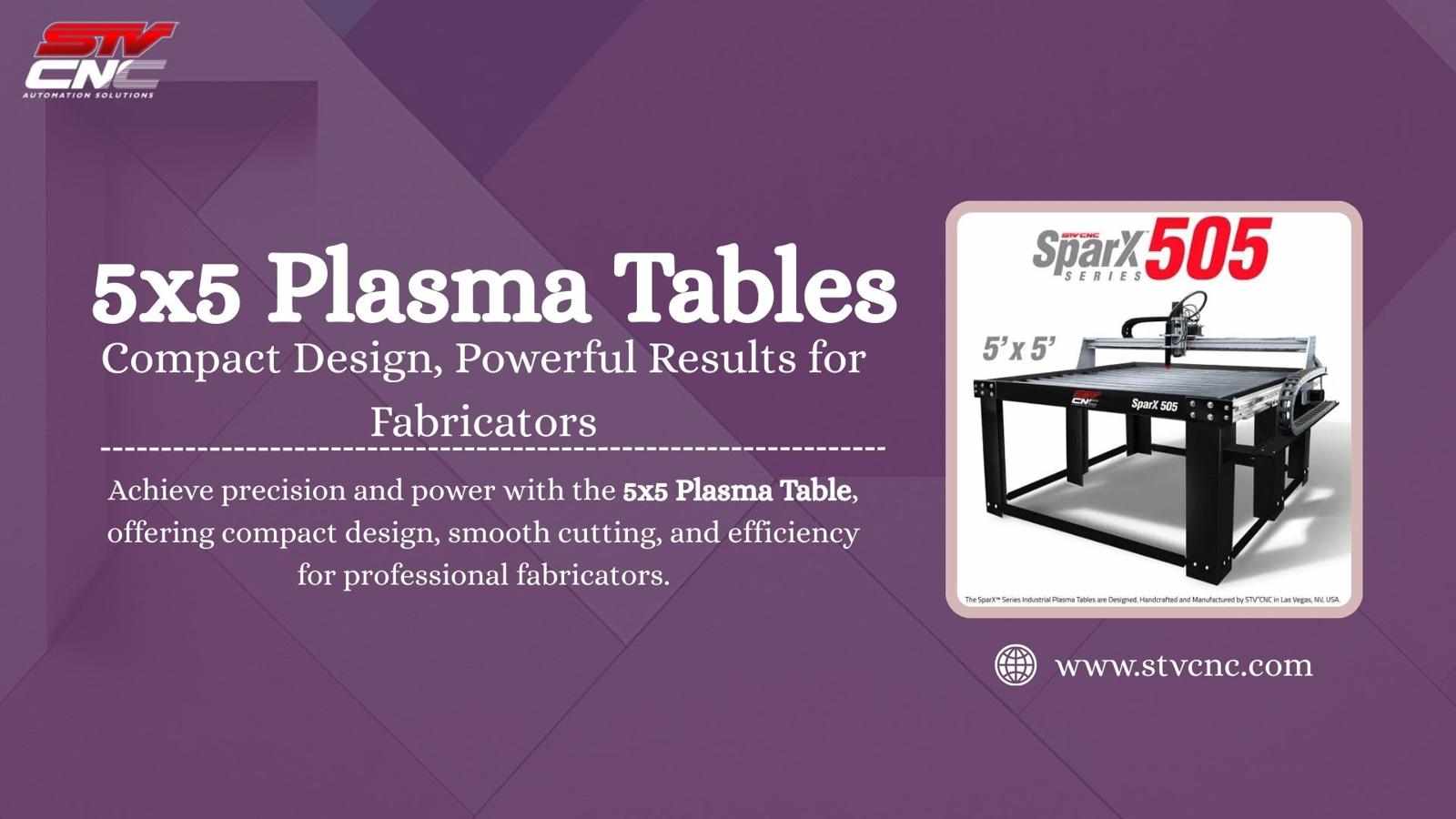

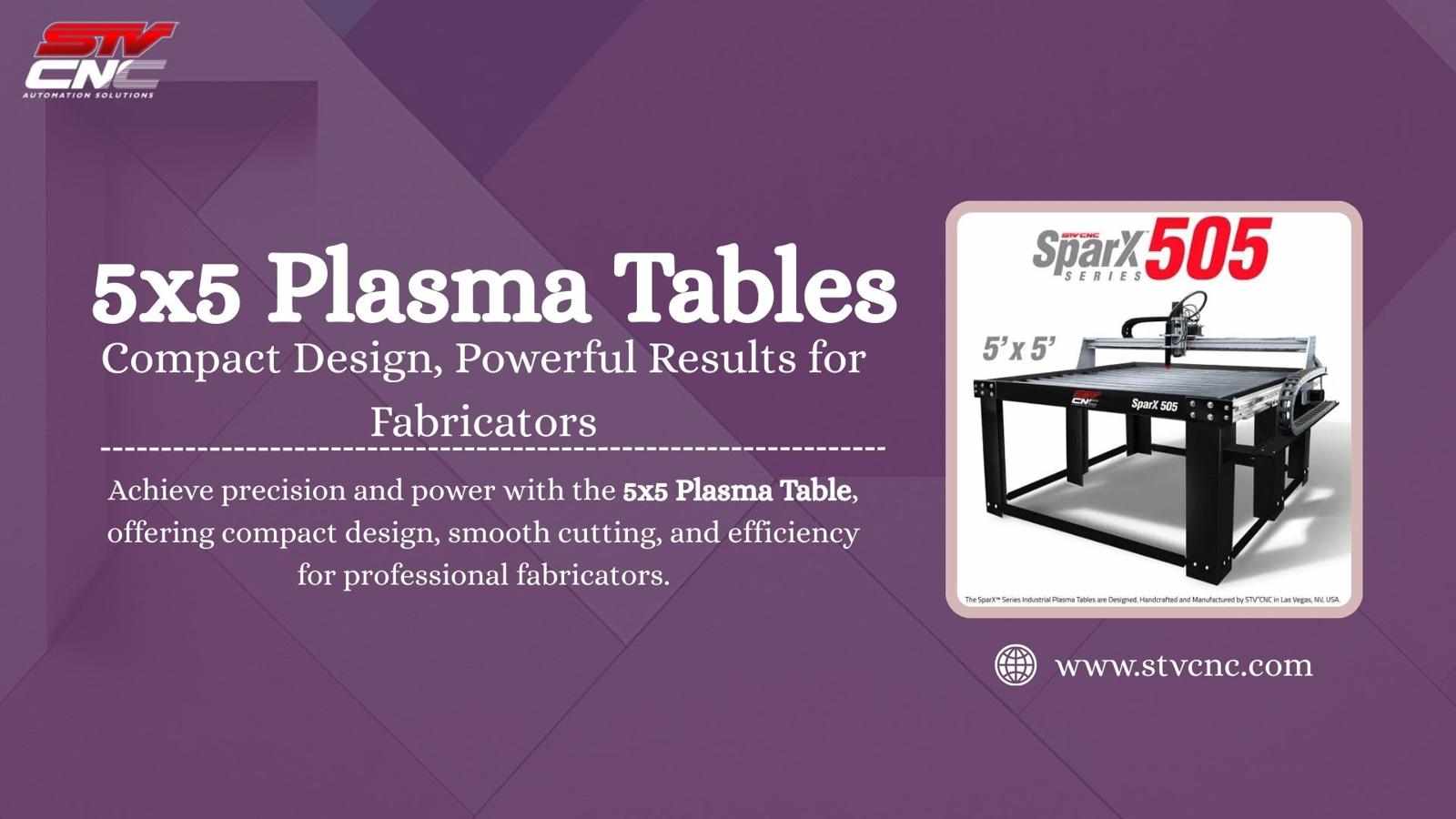

Your own personal metal shop may be the 5x5 CNC plasma table. Use precision metal cutting to unleash your creative side. This multipurpose machine makes it easy to design and create complex metal items. Ideal for both professionals and enthusiasts.

Your own personal metal shop may be the 5x5 CNC plasma table. Use precision metal cutting to unleash your creative side. This multipurpose machine makes it easy to design and create complex metal items. Ideal for both professionals and enthusiasts.

Write a comment ...

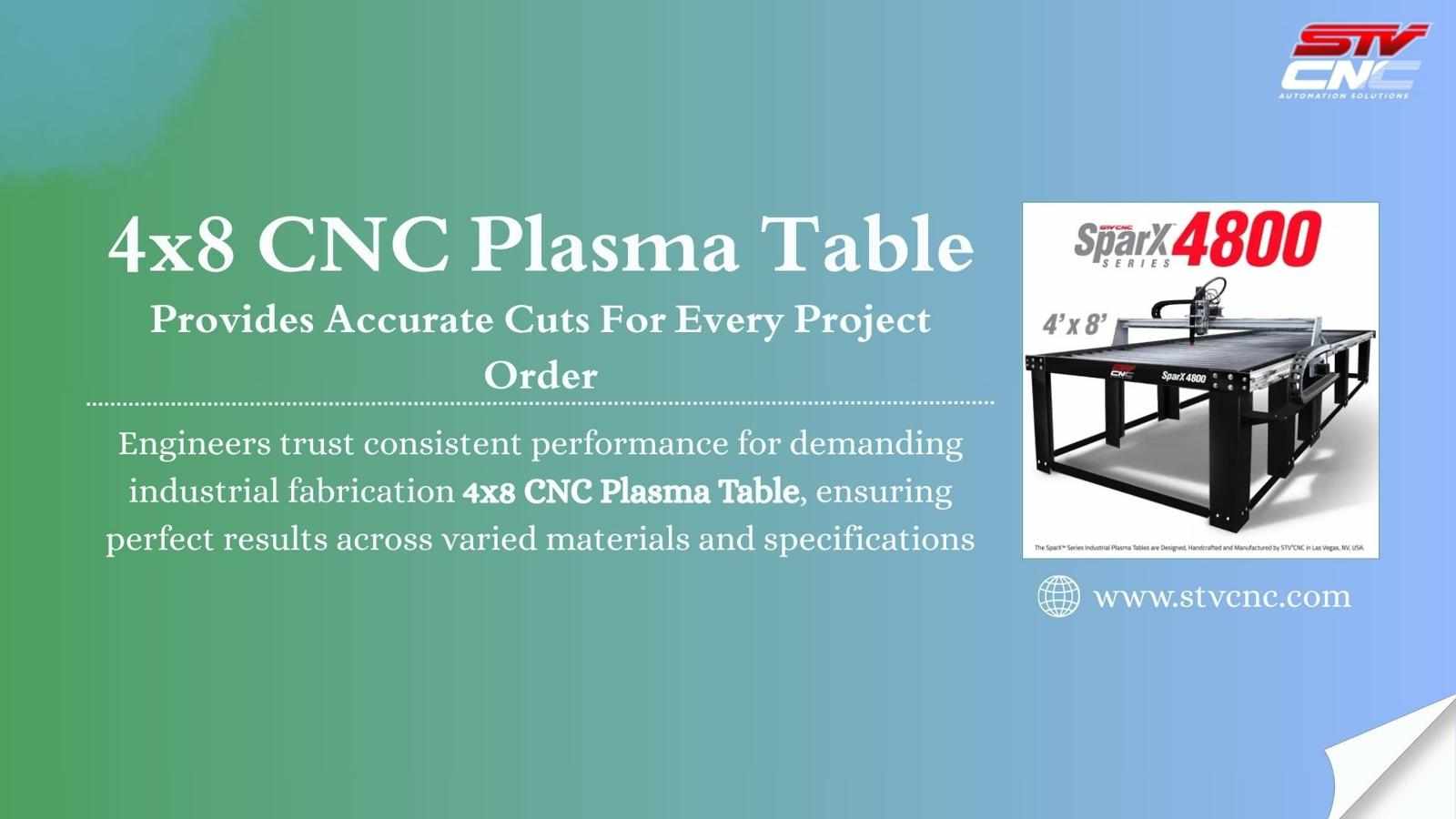

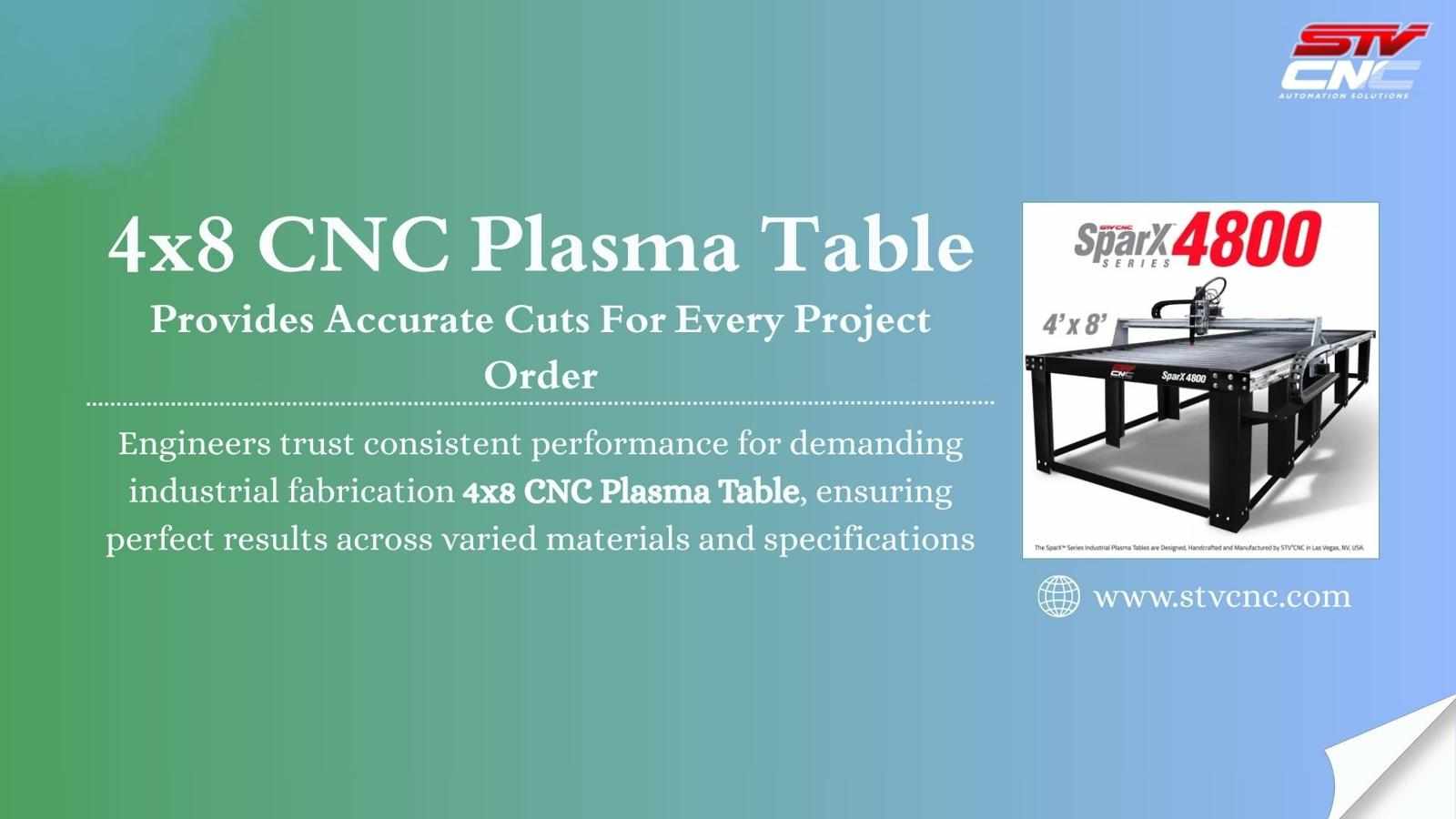

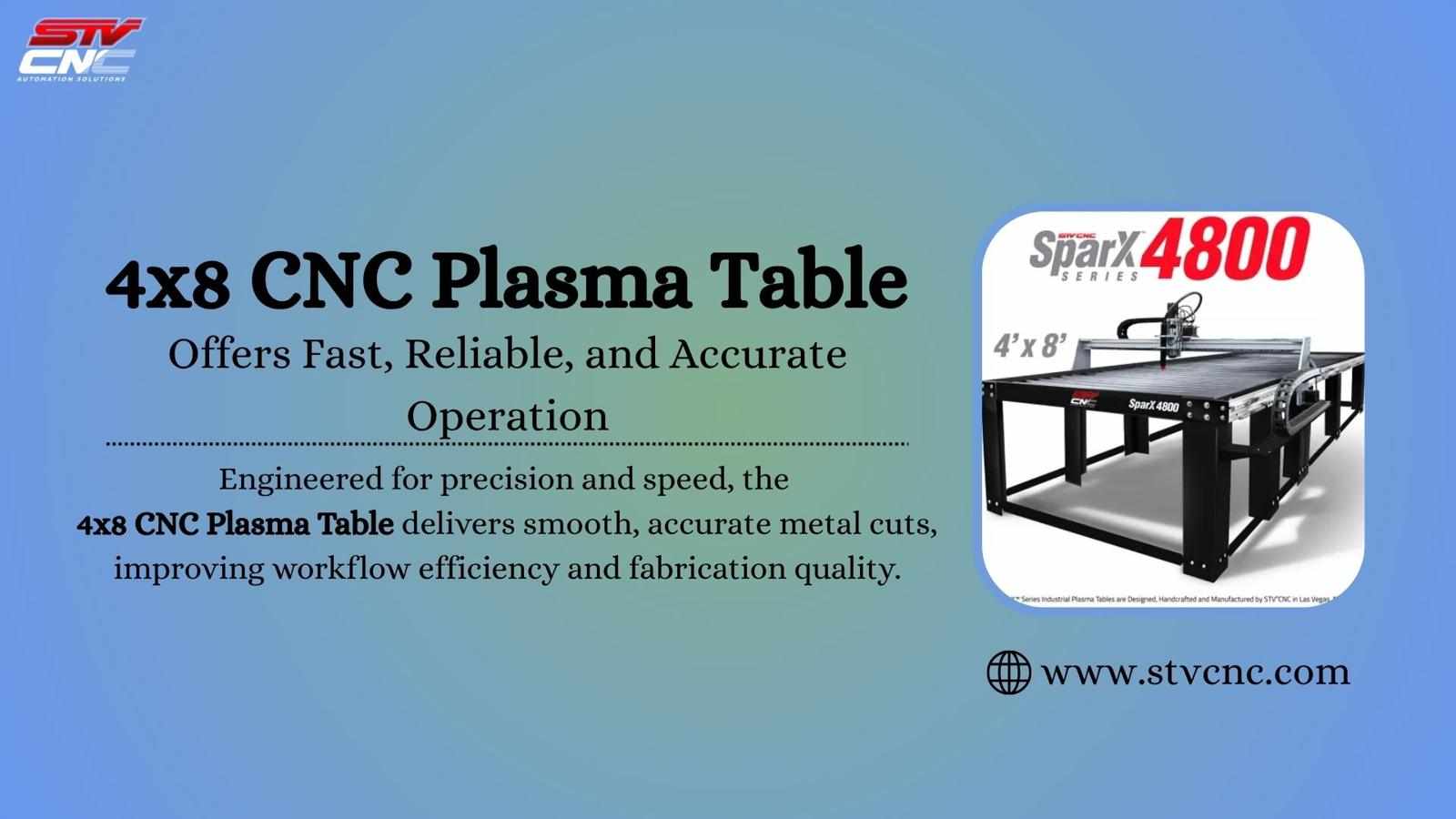

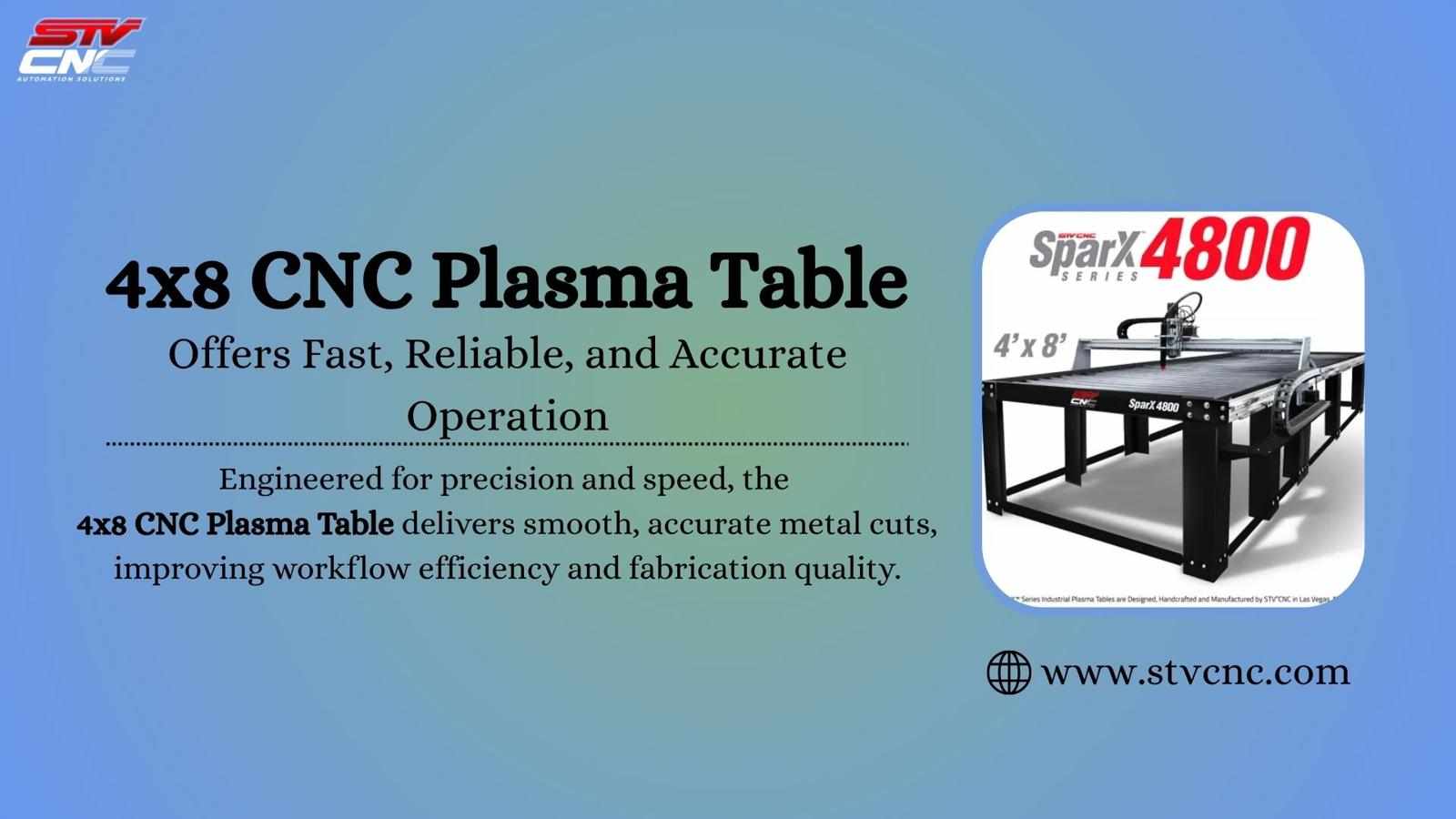

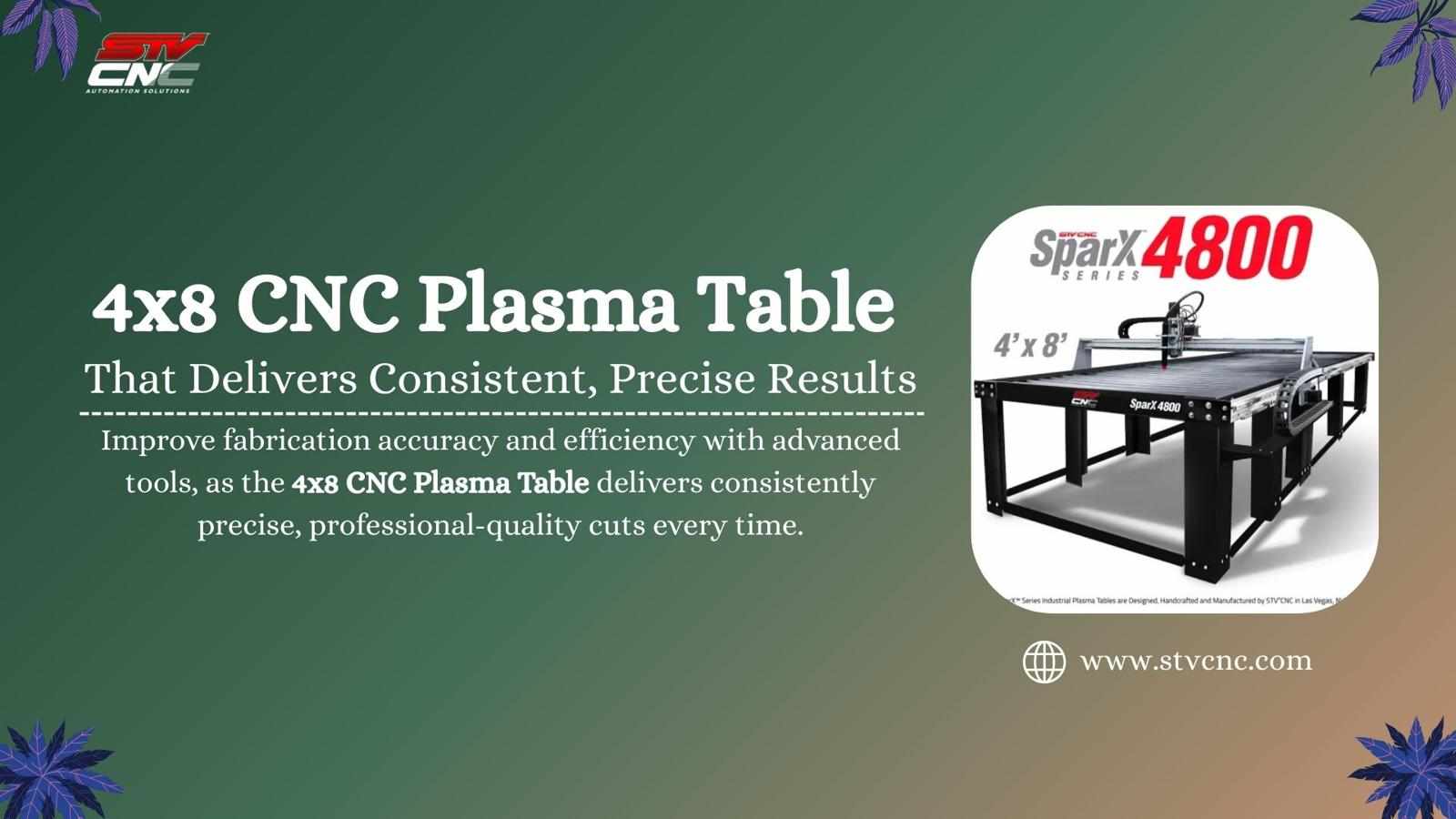

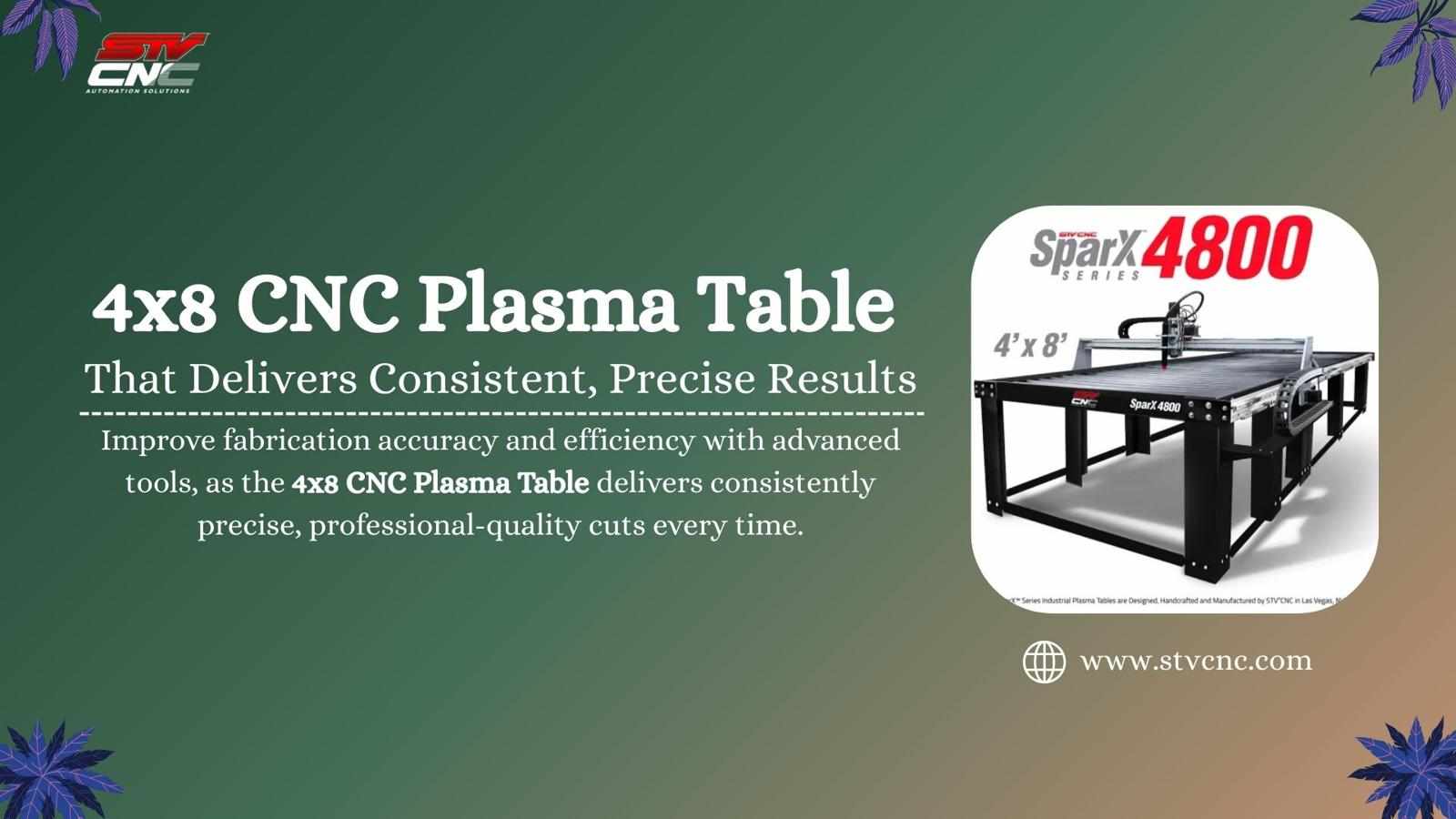

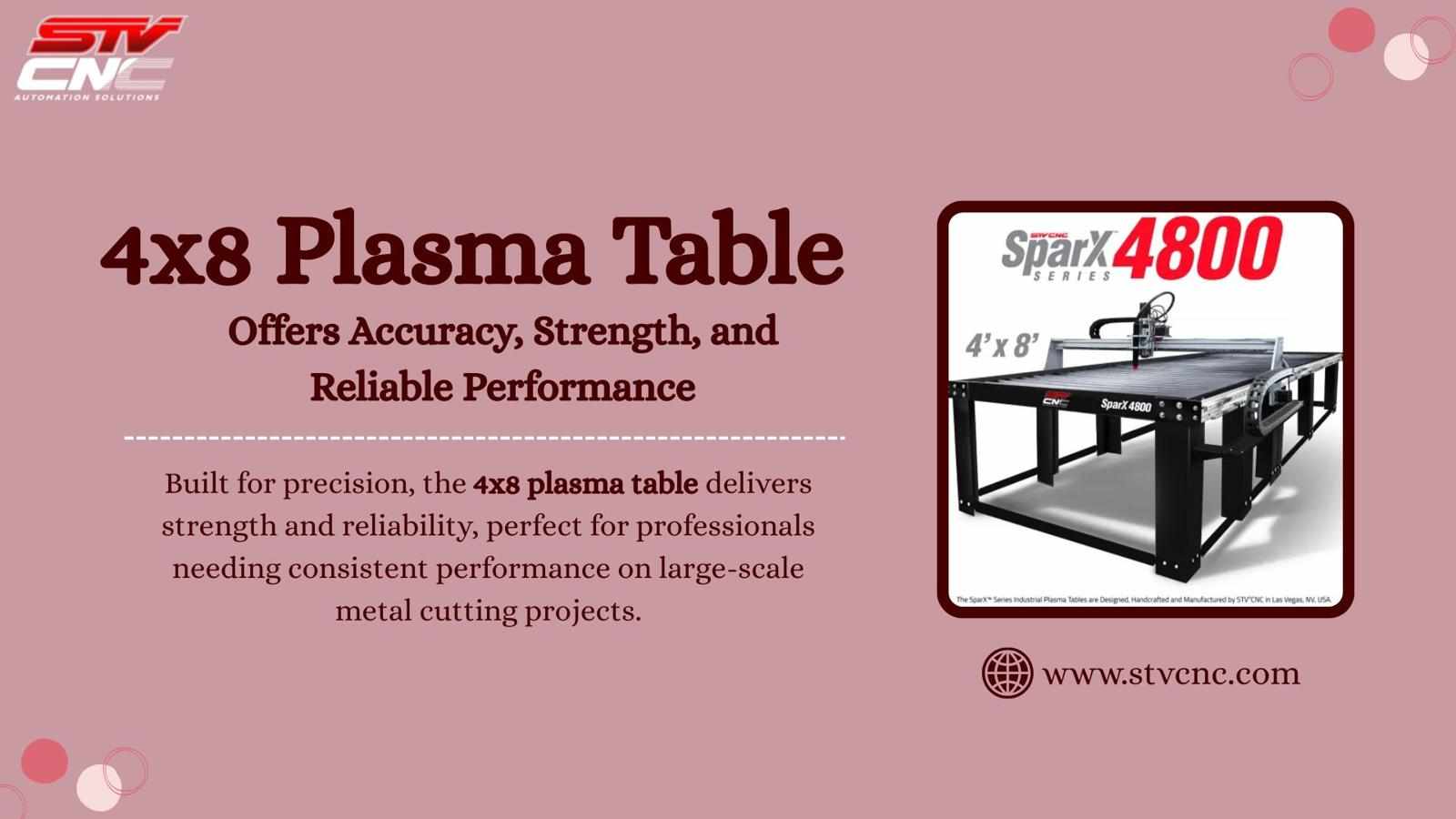

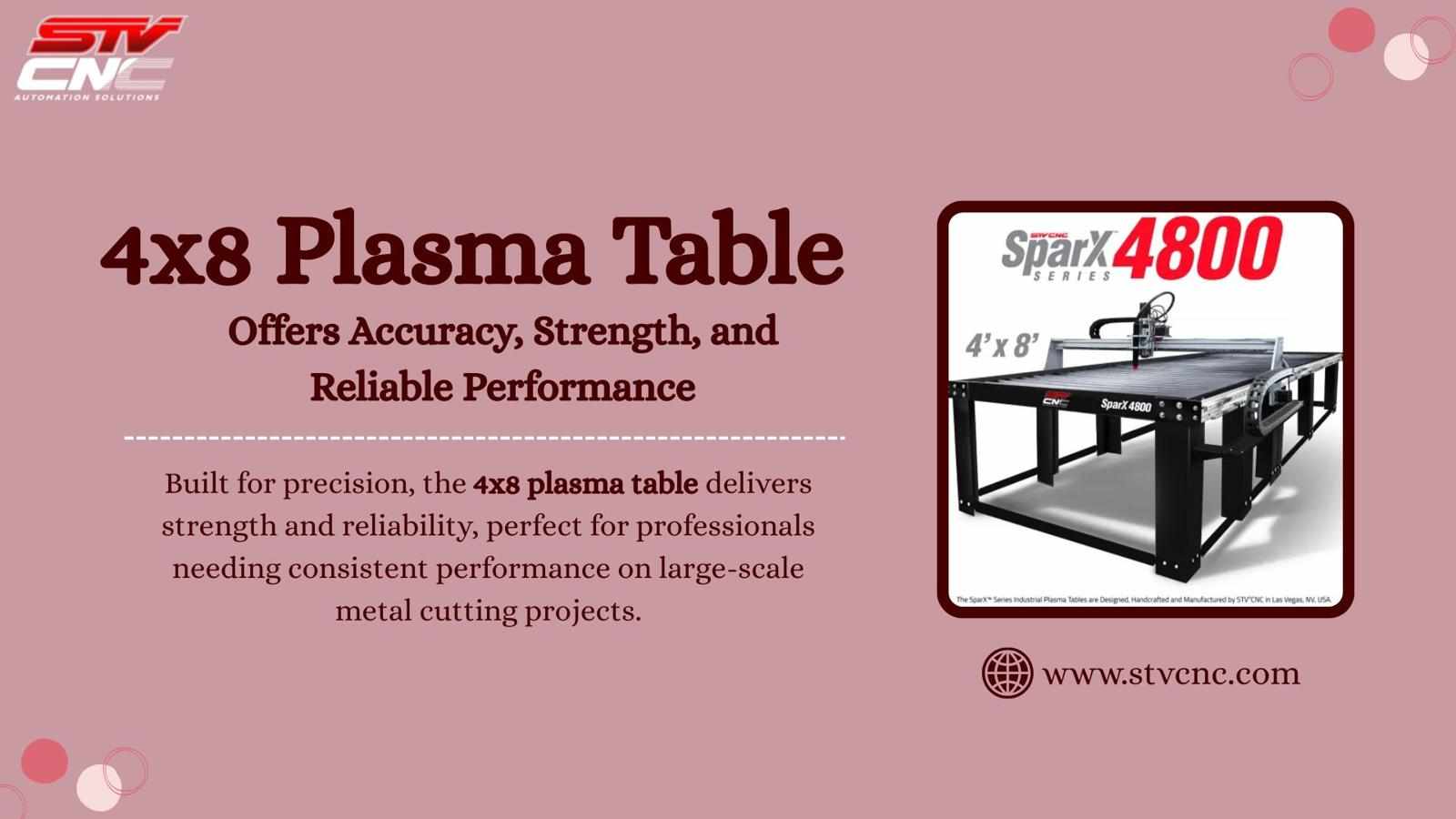

From prototypes to full-scale fabrication, accuracy and speed decide profitability and customer trust; a 4x8 CNC Plasma Table empowers workshops with clean edges, tight tolerances, and output, reducing waste, accelerating timelines, and ensuring every order meets specifications without rework delays.

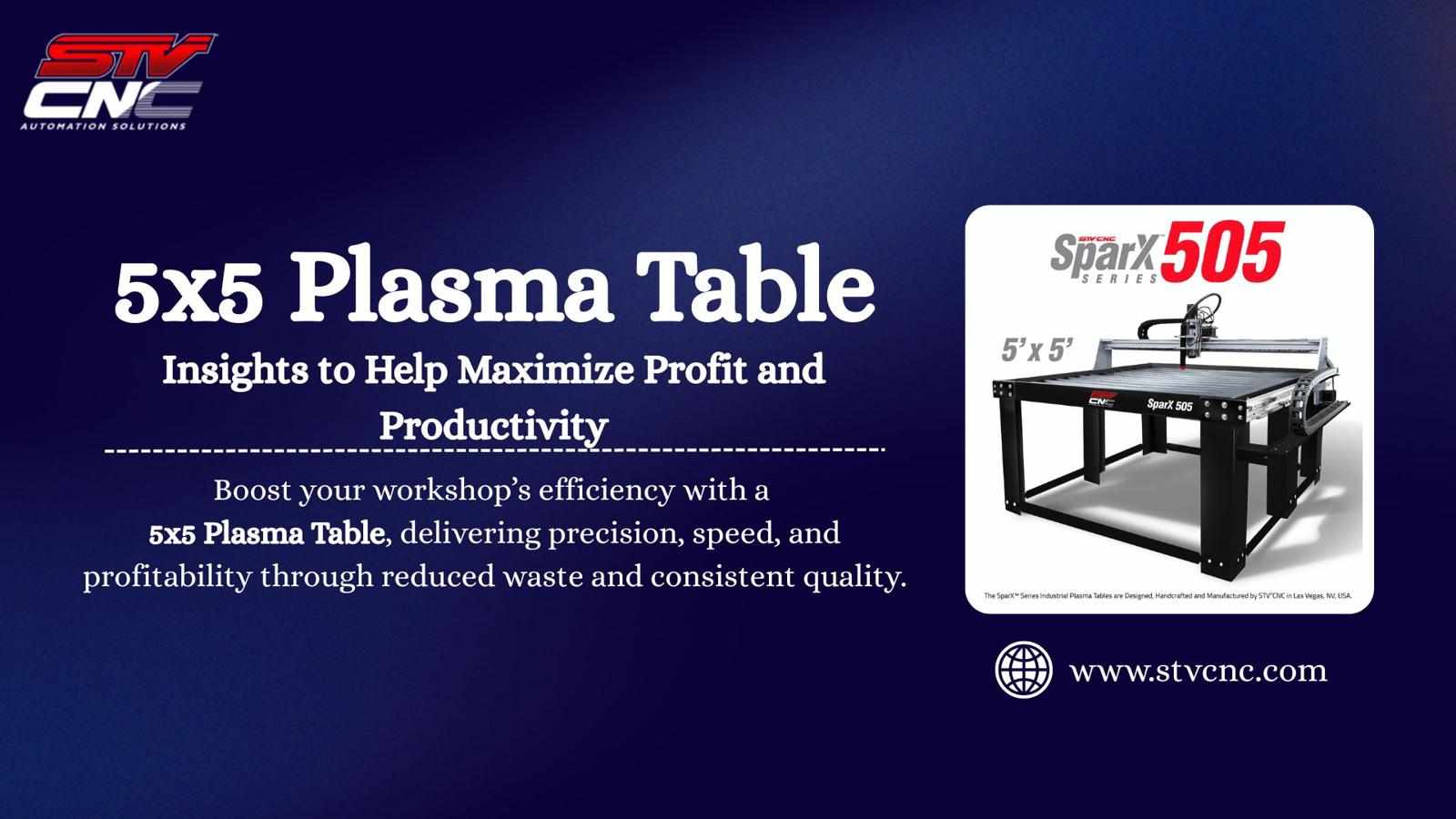

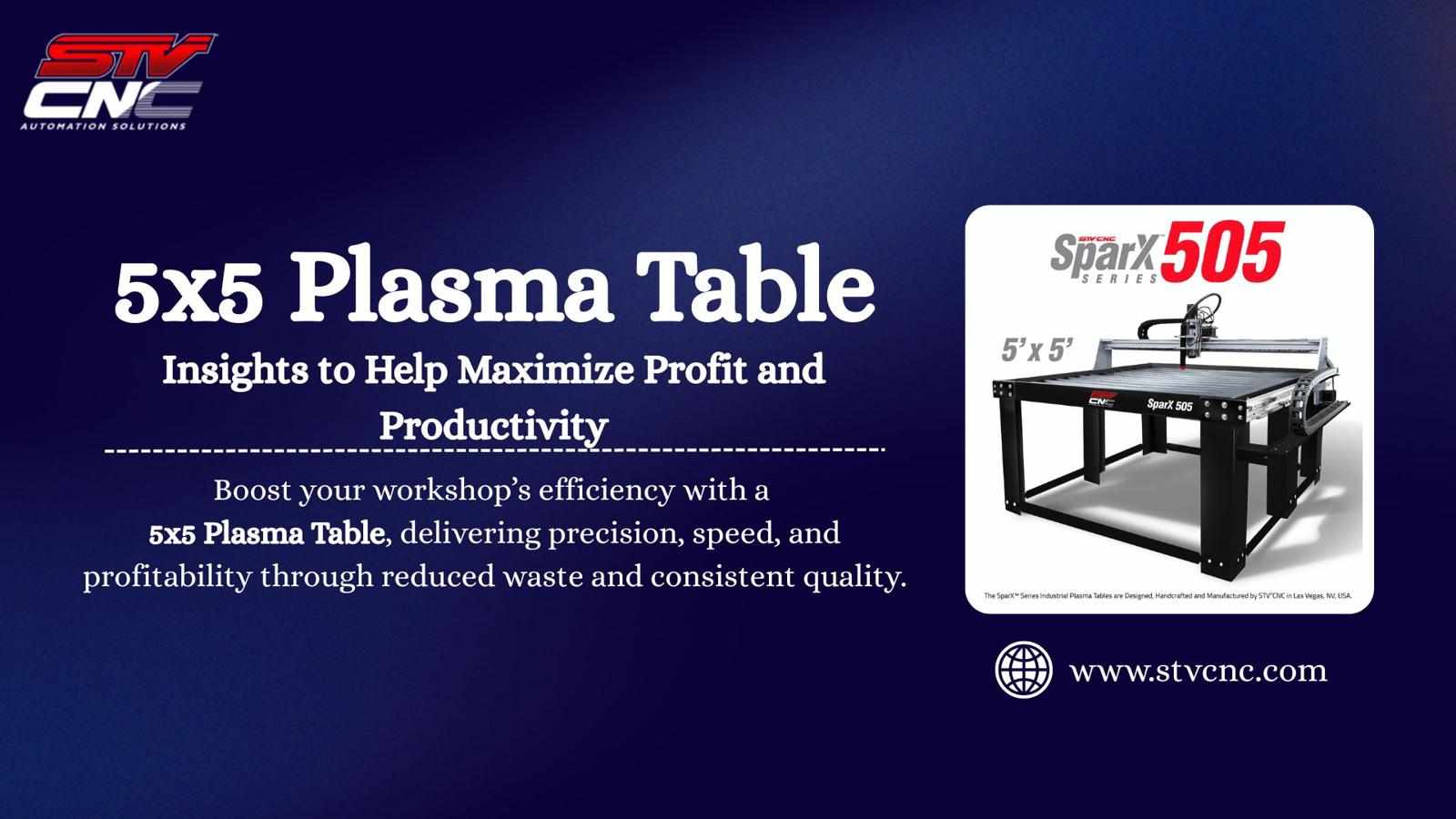

A powerful cutting system ensures smooth performance on demanding fabrication projects. With advanced control technology, a 5x5 Plasma Table offers clean, precise cuts on thick industrial metal sheets. Its stability and accuracy help metalworkers achieve consistent, high-quality results for everyday production needs.

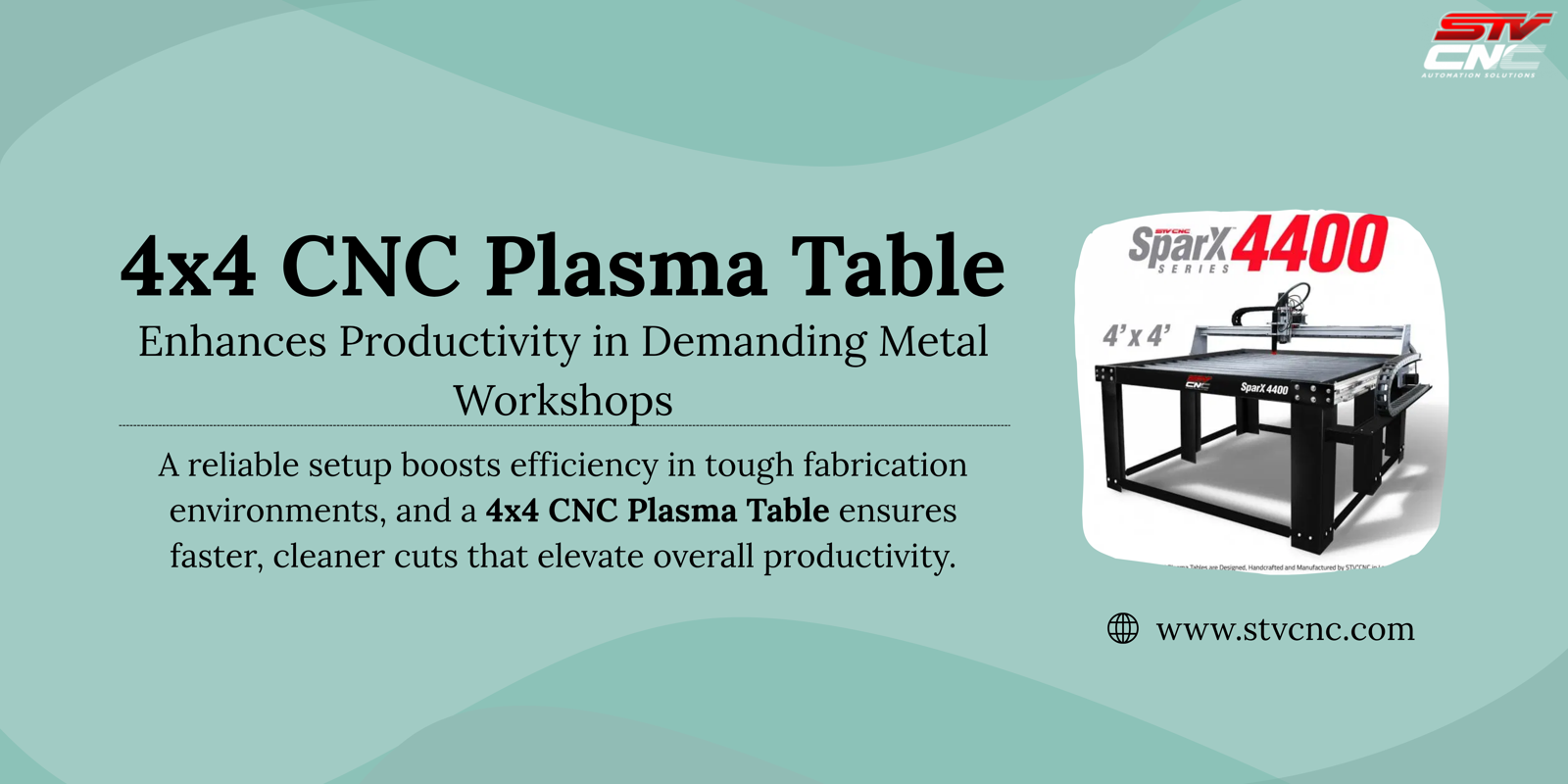

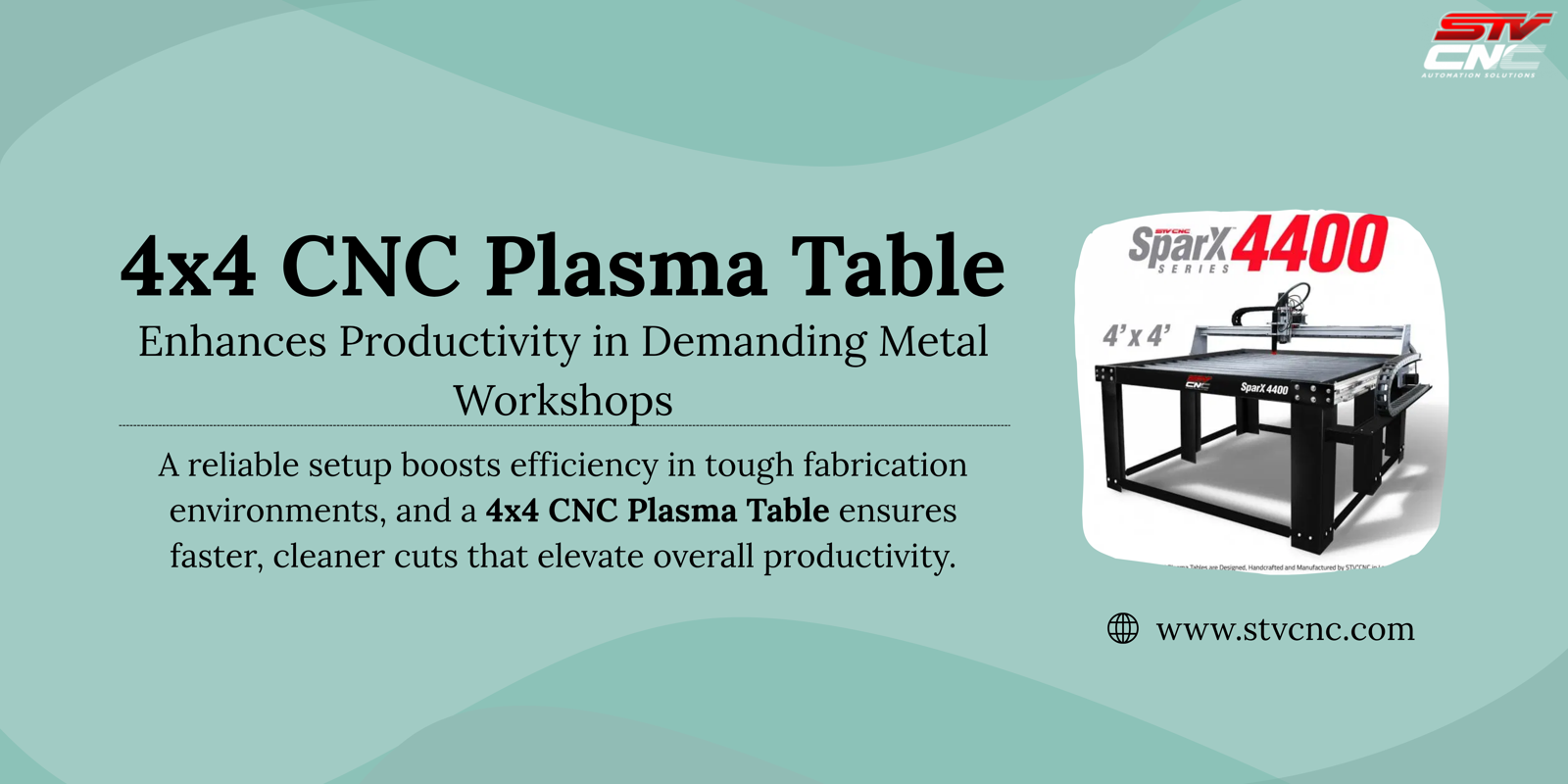

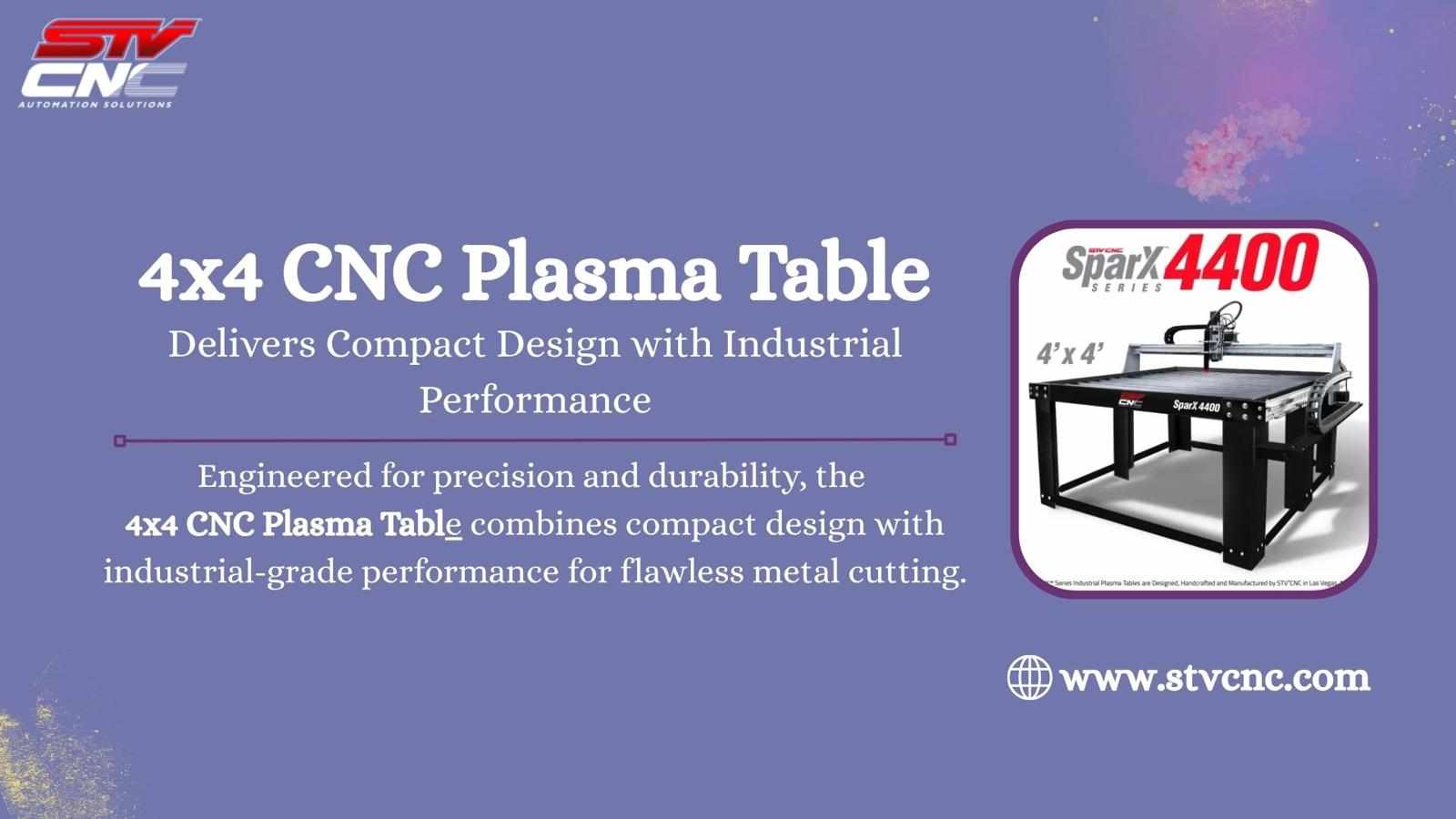

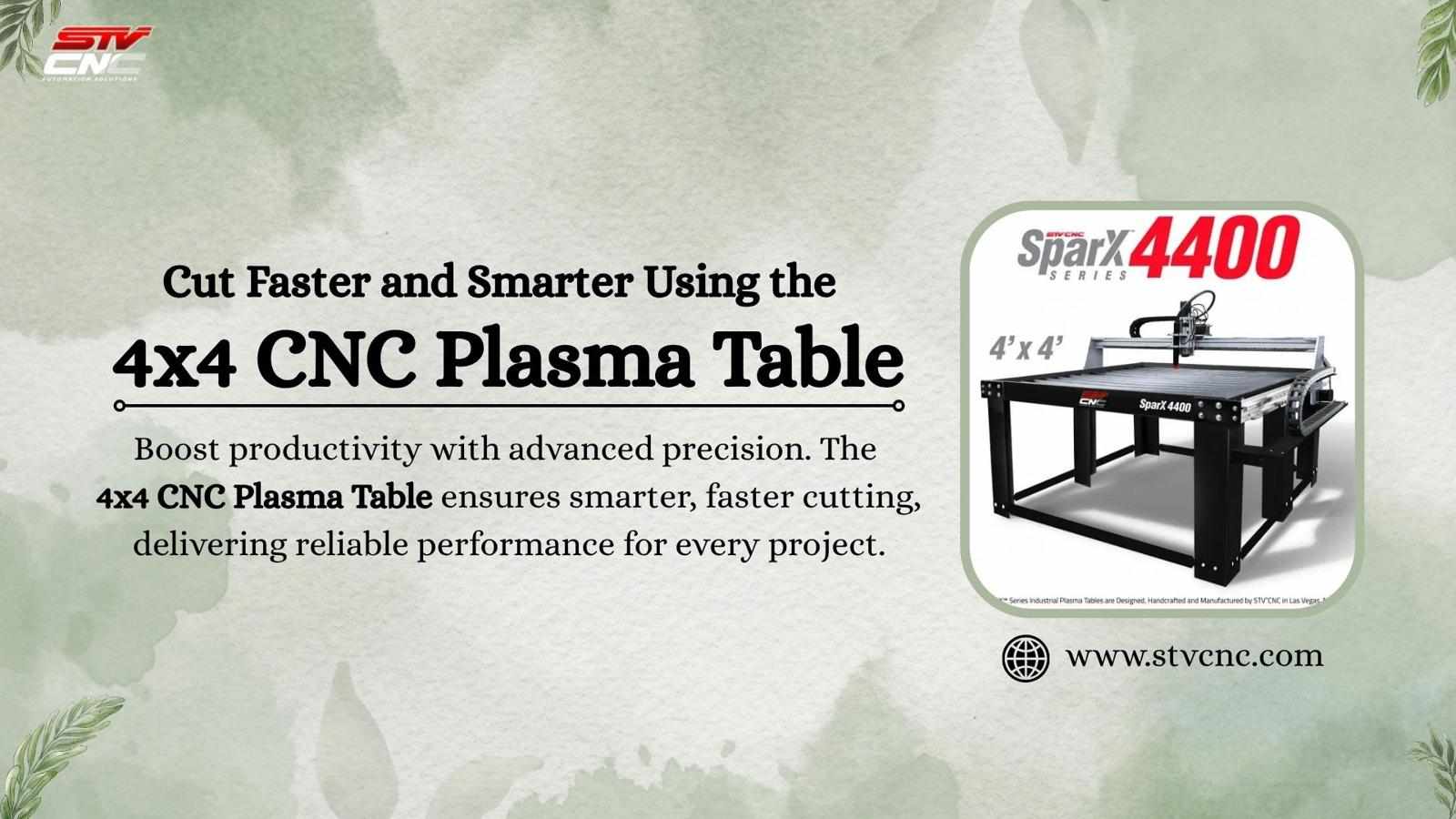

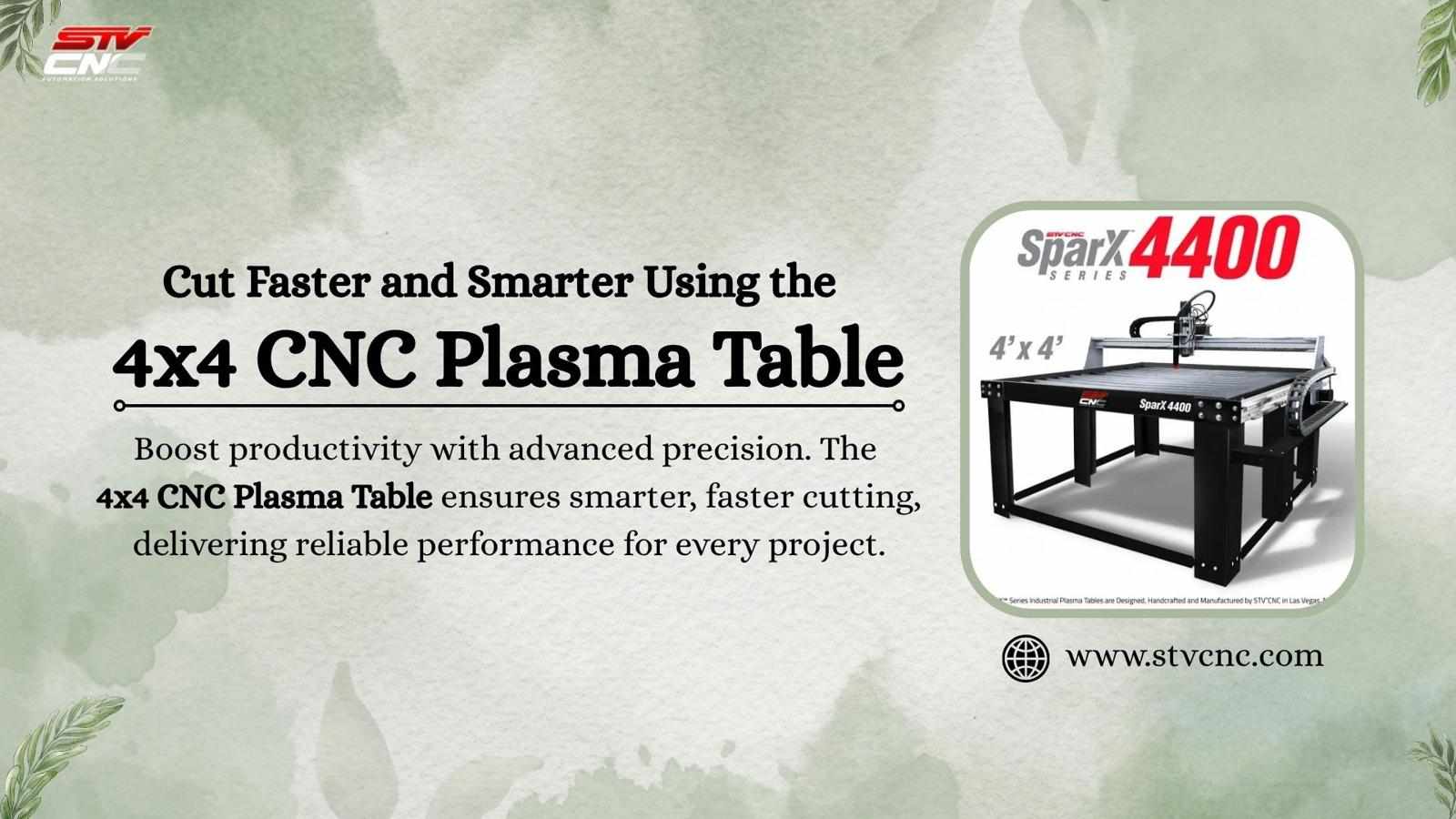

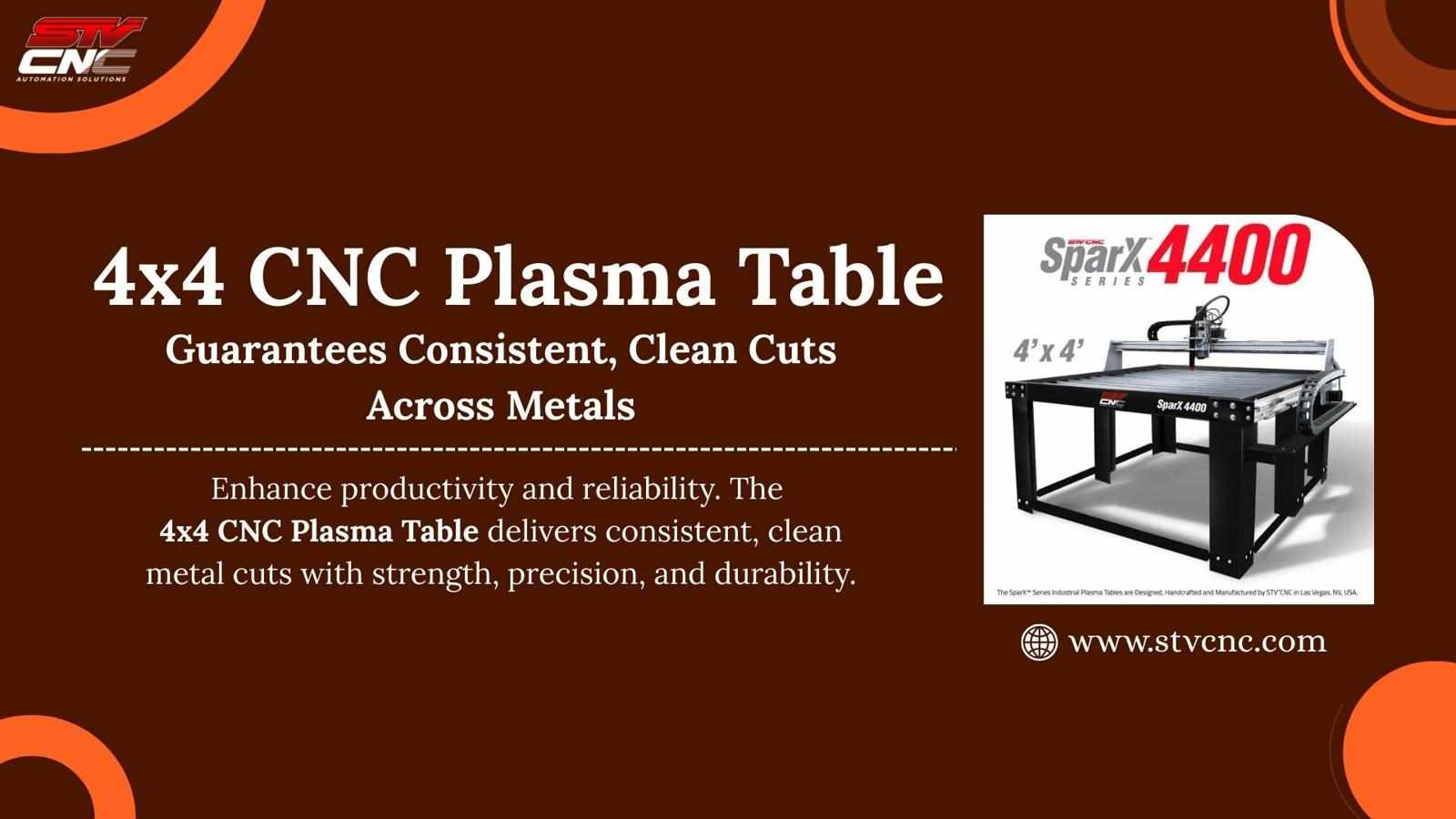

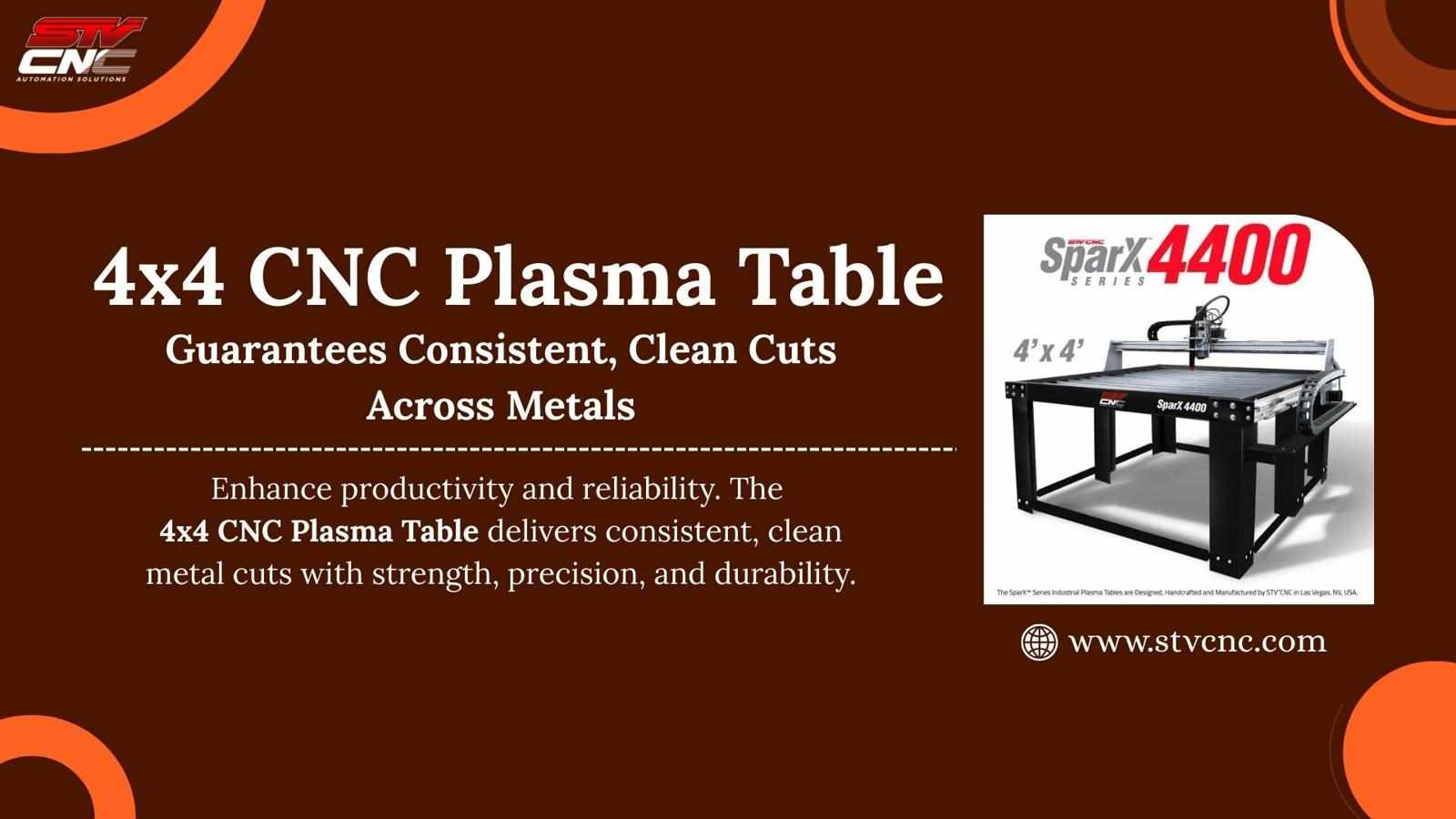

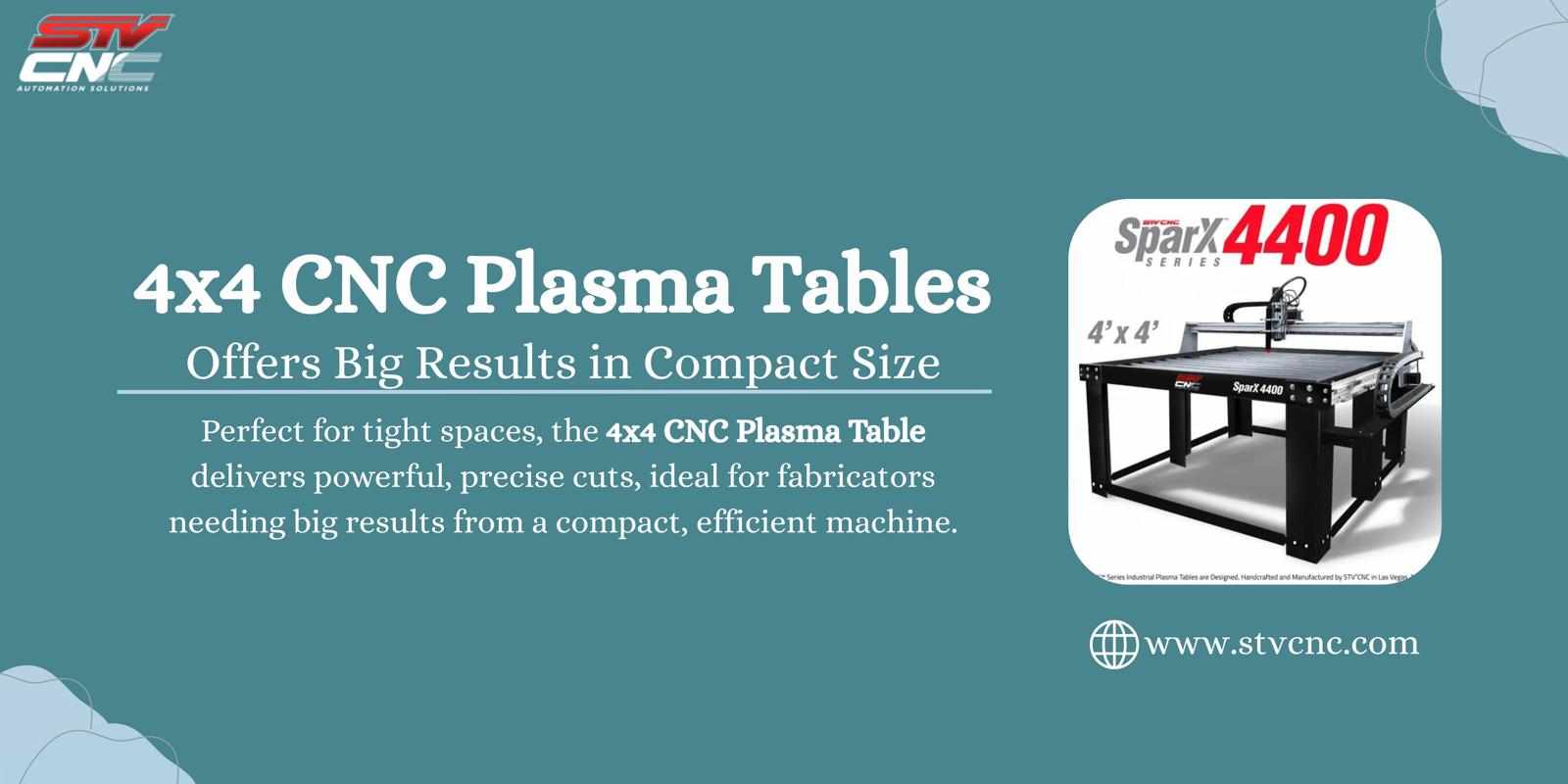

Demanding metal workshops need reliable equipment that supports speed, accuracy, and consistent output. A 4x4 CNC Plasma Table provides strong cutting power and precise control, helping fabricators streamline workflows, handle complex projects effortlessly, and significantly boost overall productivity.

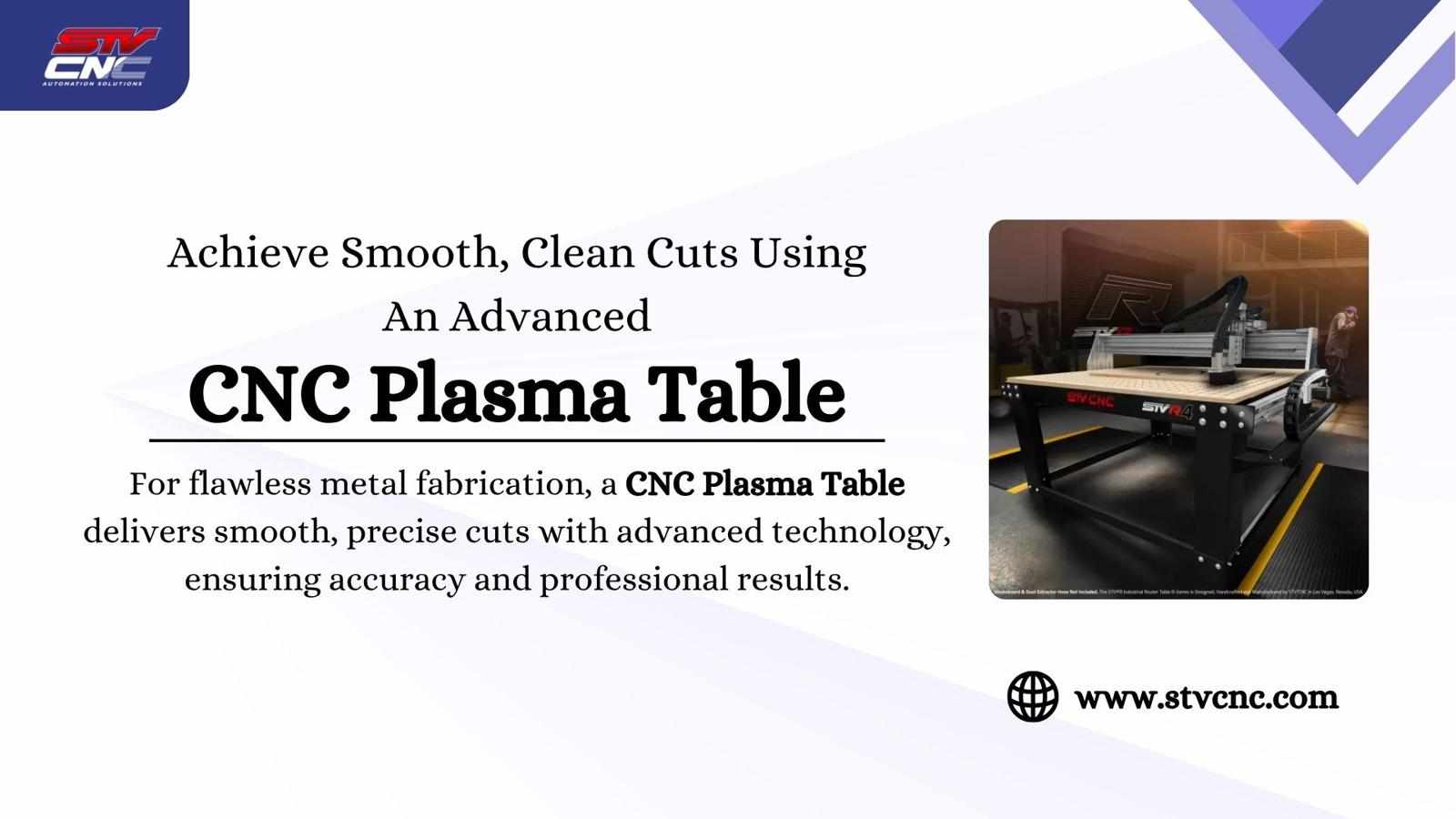

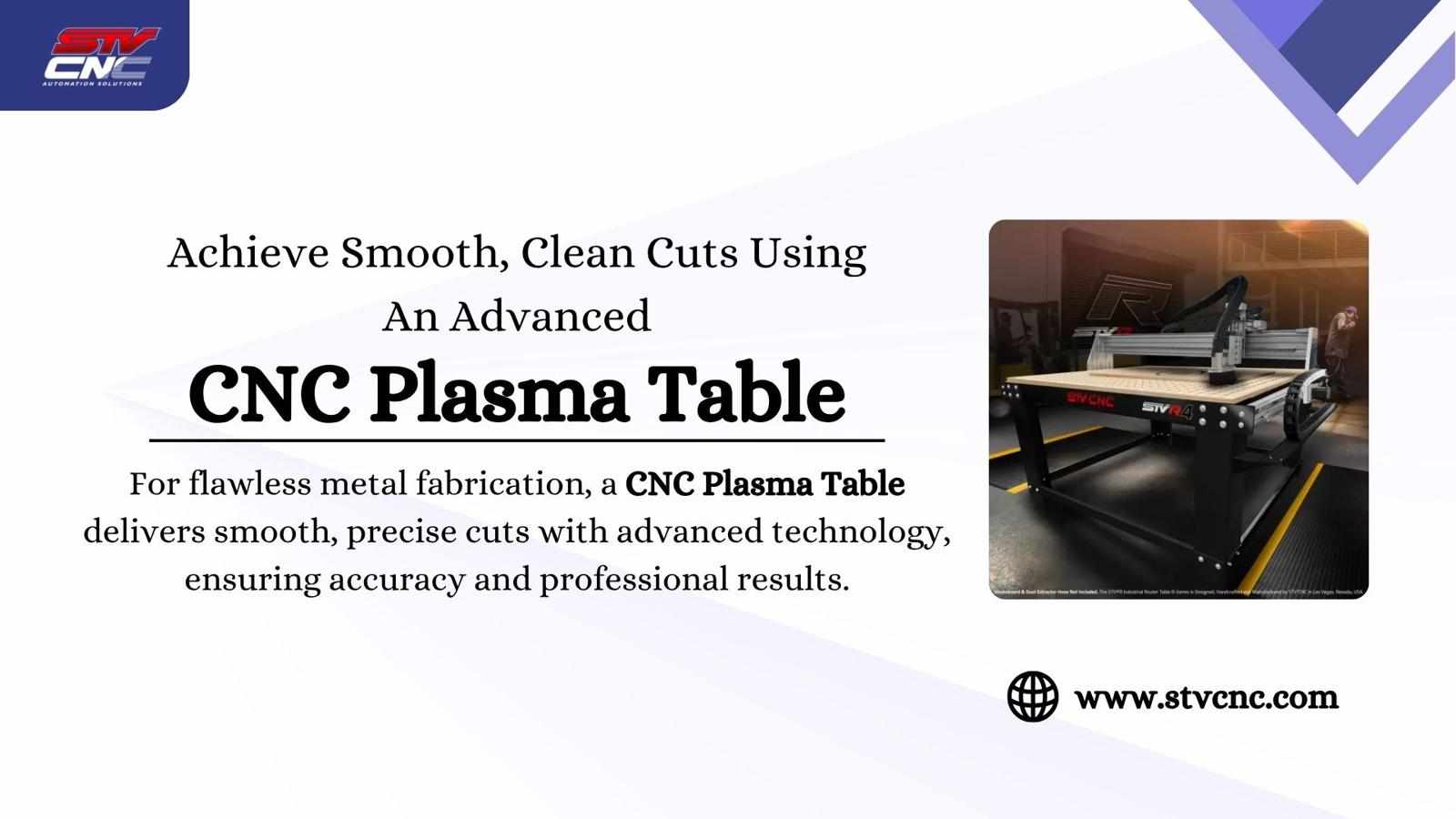

For precise and efficient metal cutting, the CNC Plasma Table offers advanced technology that delivers smooth, clean edges every time—ensuring superior quality, reduced waste, and reliable performance for both industrial and custom fabrication projects.

Precision, speed, and durability come together for efficient metal fabrication performance. Engineered for consistent results, the 4x8 CNC Plasma Table delivers smooth, accurate cuts with minimal waste. Ideal for workshops that demand fast operation, reliability, and professional-quality output on every project.

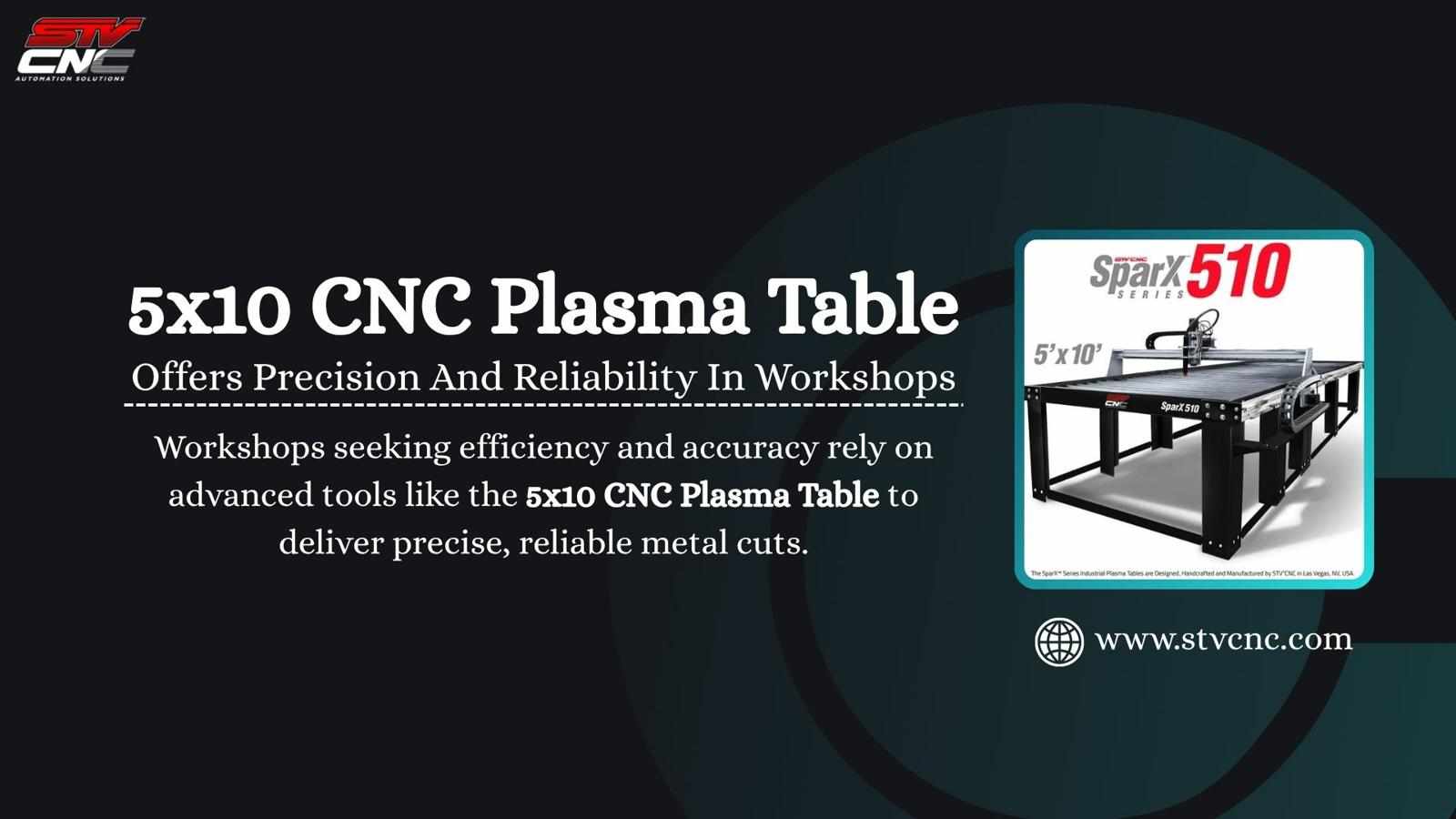

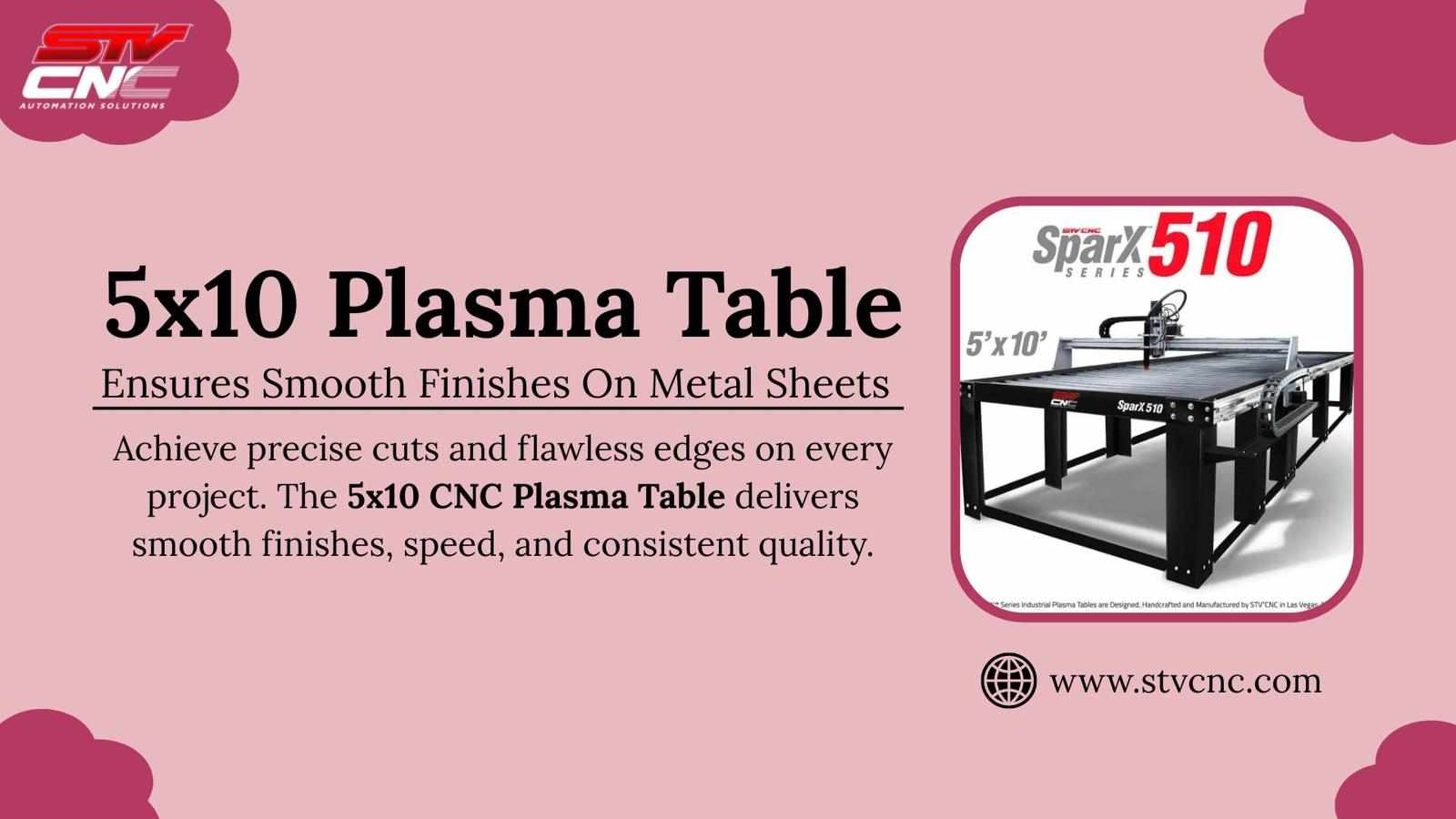

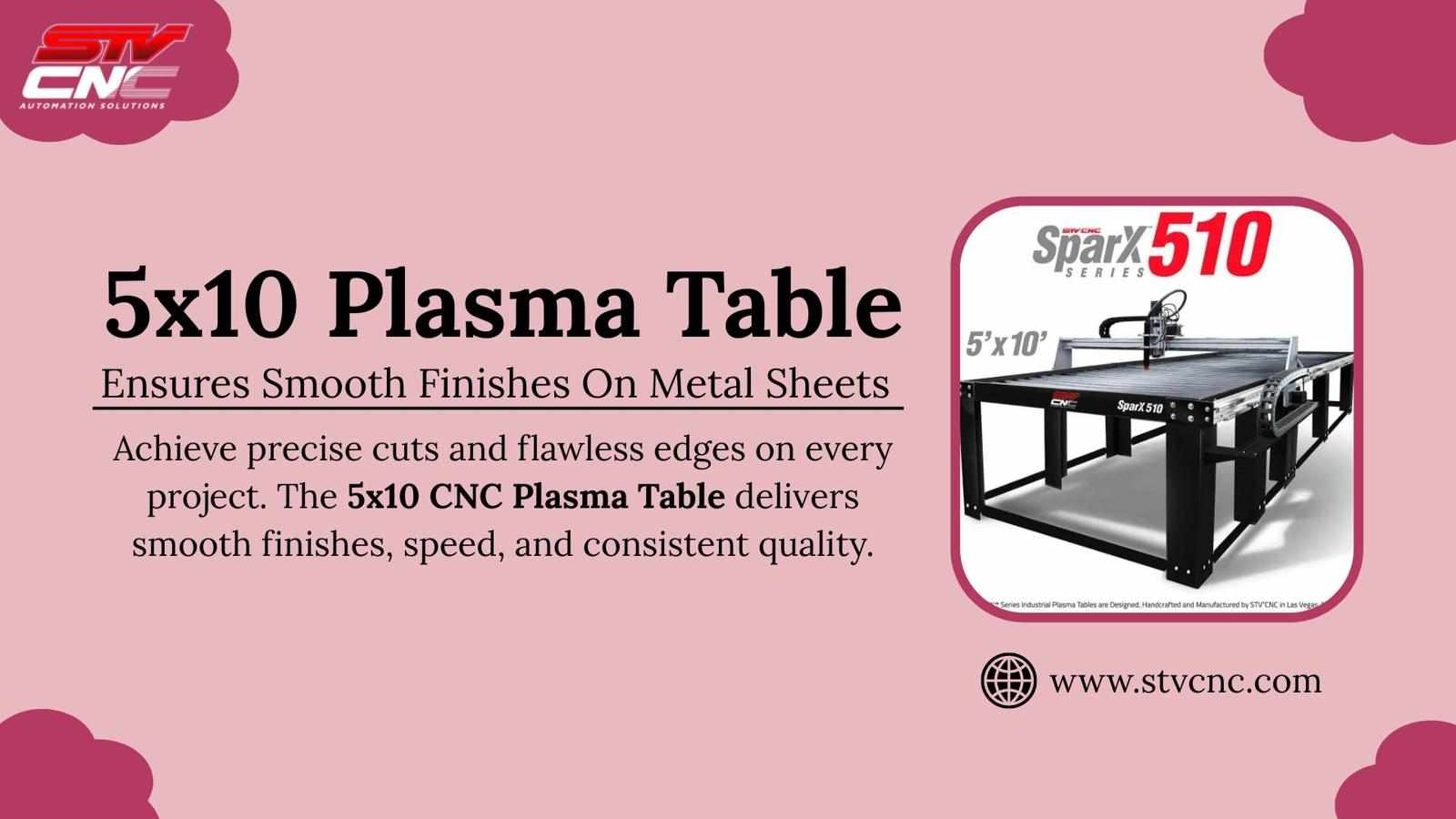

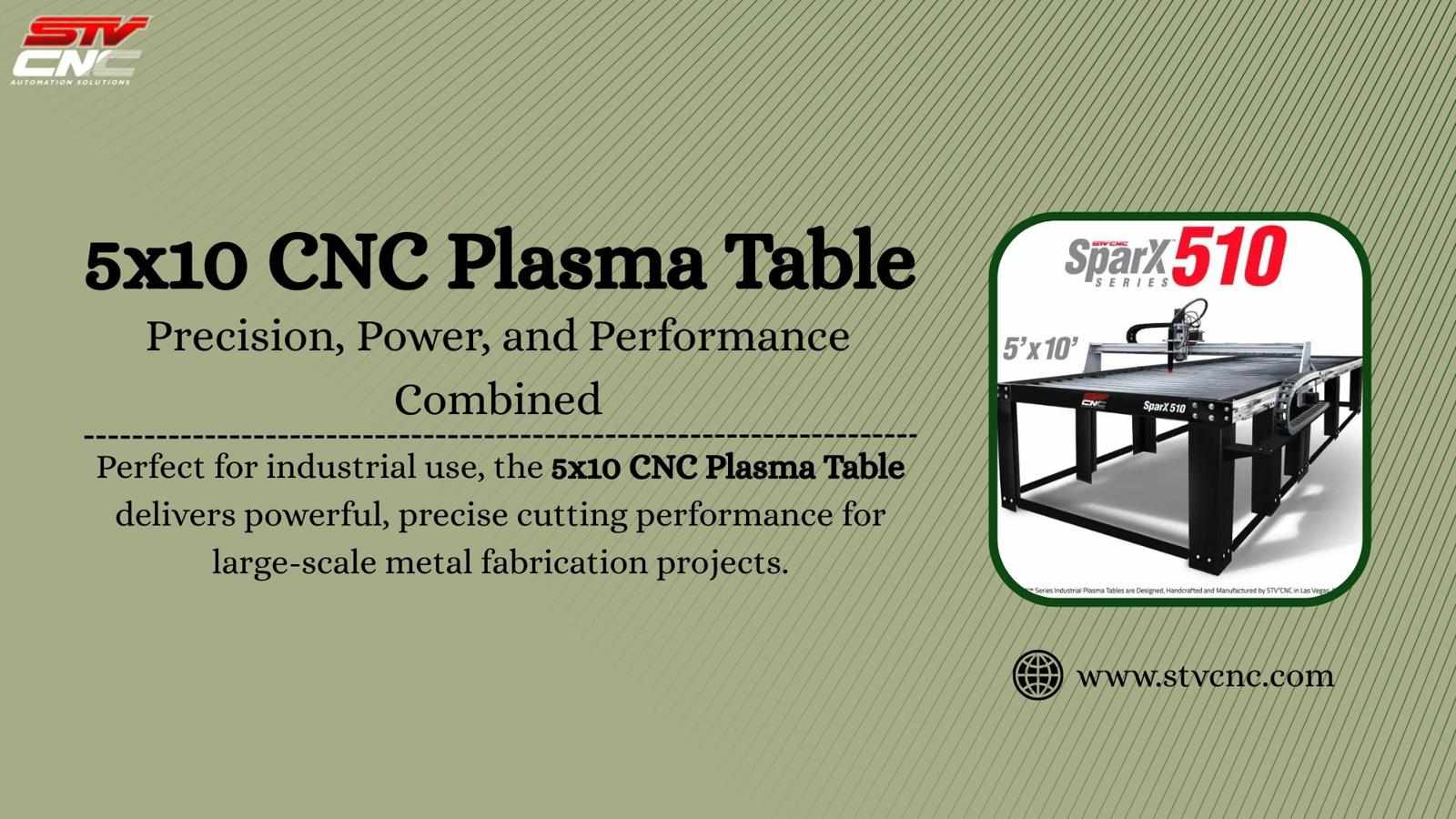

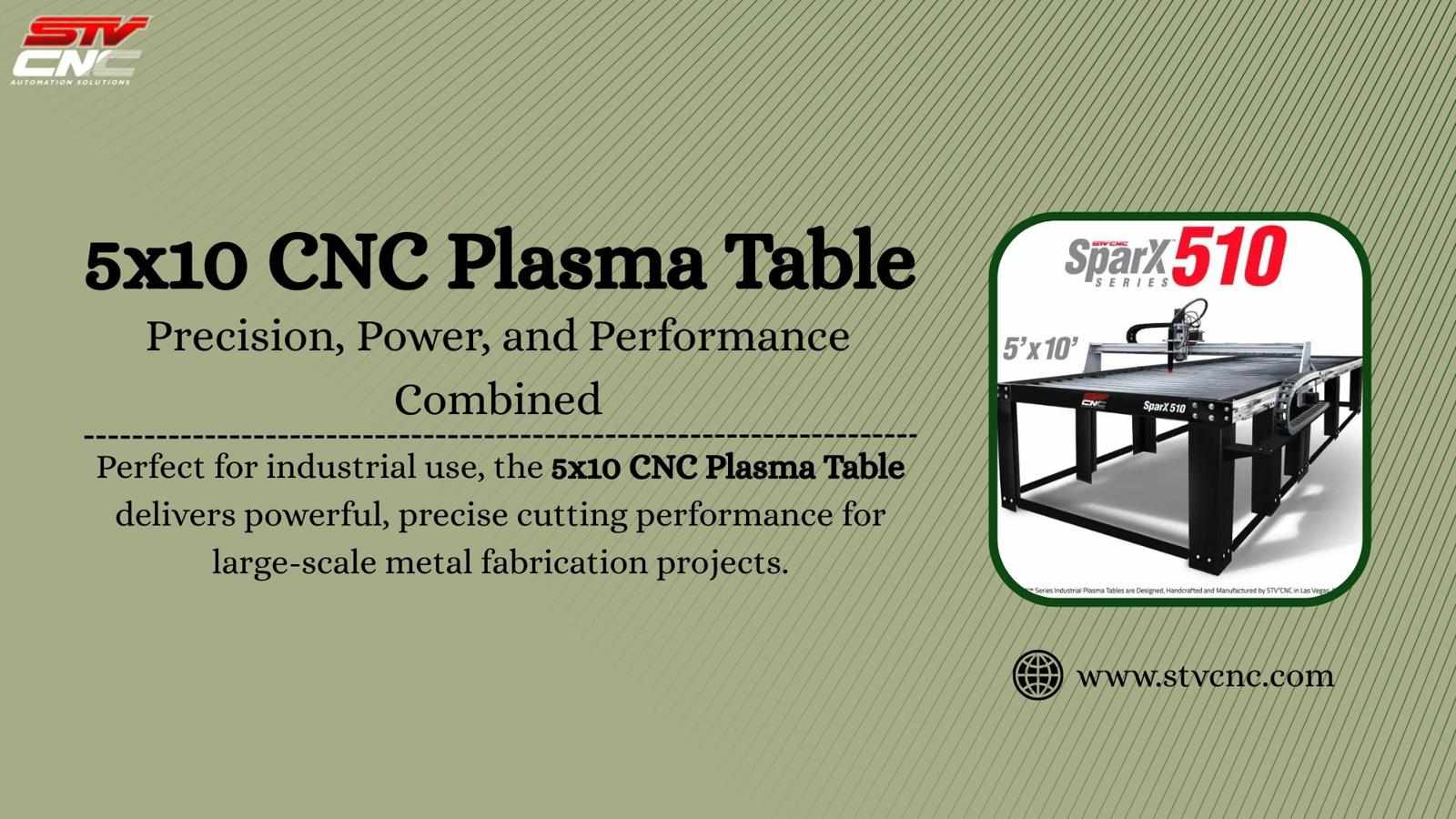

For metal fabrication projects requiring accuracy and efficiency, the 5x10 Plasma Table makes intricate cutting simple and precise. It delivers clean, consistent results on steel, aluminum, and other metals, enhancing productivity and professional-quality workmanship every time.

Built for precision and durability, the 4x4 CNC Plasma Table combines a compact footprint with powerful industrial performance. Ideal for small workshops, it ensures accurate, clean metal cuts, maximizing efficiency and productivity without compromising on quality or strength.

For metalworking professionals, accuracy and consistency are essential. The 5x10 CNC Plasma Table delivers precise cuts and dependable performance, helping workshops complete complex projects efficiently while ensuring high-quality results for every custom fabrication task.

Boost productivity and accuracy with advanced metal cutting solutions. The 4x4 CNC Plasma Table delivers smooth performance, precise cuts, and reliable efficiency. Designed for fabricators, it helps complete projects faster while minimizing waste, saving both time and resources.

Take your metal fabrication projects to the next level with advanced tools designed for accuracy. The versatile 4x8 CNC Plasma Table delivers consistent, precise results, improving efficiency, reducing errors, and ensuring professional-quality cuts every time.

A 5x5 CNC Plasma Table delivers unmatched accuracy and efficiency, making complex designs simple. With the 5x5 CNC Plasma Table, metalworkers can achieve precise cuts, streamline production, and handle every metal project with confidence and speed.

Achieve precise, clean, and professional metal cuts every time. With the 5x10 CNC Plasma Table, workshops experience faster cutting, consistent quality, and smooth finishes, making fabrication more efficient, reliable, and perfect for every metalworking project.

Delivering accuracy and dependability, this cutting solution enhances productivity for workshops and manufacturers alike. The 4x4 CNC Plasma Table ensures consistent, clean cuts across metals, combining strength, precision, and durability to meet the demanding needs of industrial fabrication projects.

Experience unmatched precision and productivity in a space-saving design. The 5x5 Plasma Table combines compact structure with powerful cutting performance, ensuring smooth, accurate results. Perfect for fabricators seeking efficiency, it transforms workshops with reliable technology built for professional-grade metalworking projects.

Achieve outstanding results with advanced cutting technology. The 4x8 CNC Plasma Table offers the perfect balance of power and precision, making it ideal for fabricators who need accuracy, speed, and durability to handle demanding metalworking projects with confidence.

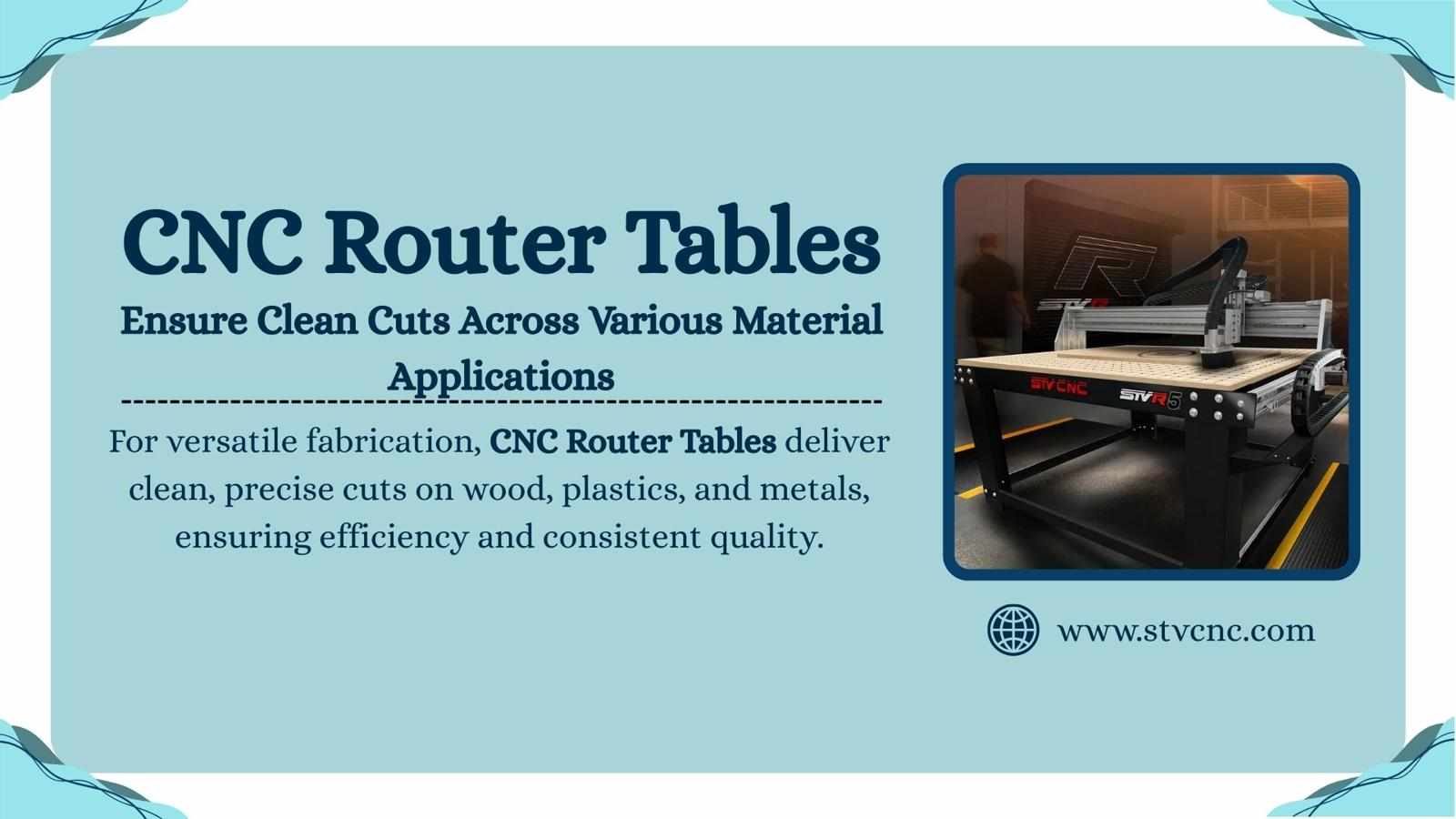

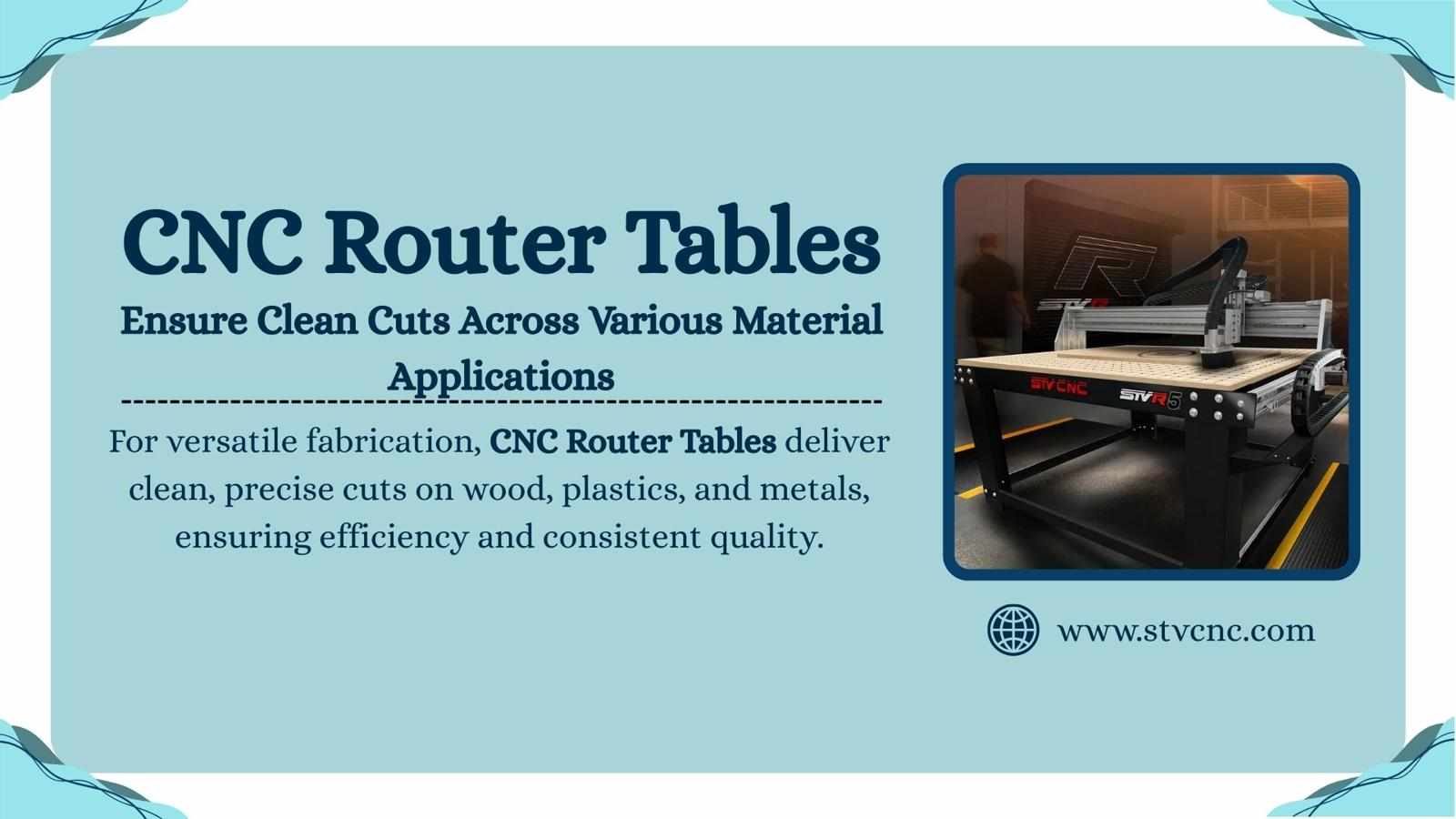

Workshops need versatile tools that handle different materials with precision. CNC Router Tables guarantee clean, accurate cuts on wood, plastics, and metals, making them essential for professionals seeking efficiency, consistency, and quality across diverse fabrication and design applications.

Learn essential safety practices to ensure efficient and accident-free metal cutting. A 5x5 Plasma Table requires proper training, protective gear, and routine maintenance, helping operators achieve precision results while minimizing risks and maintaining a safe, productive workspace for every project.

The 5x10 CNC Plasma Table combines precision, power, and high-performance cutting in one robust machine. Perfect for large-scale metal fabrication, it delivers clean, accurate cuts every time—making it a top choice for serious professionals and industrial shops.

Engineered for serious metalwork, this machine delivers clean, consistent results every time. The 4x8 plasma table combines accuracy, strength, and long-lasting performance—making it a top choice for professionals who need reliability across large-scale cutting projects.

Ideal for small workshops, this machine delivers high-precision performance while occupying minimal space. The 4x4 CNC Plasma Table combines compact design with powerful cutting capabilities, offering big results for fabricators who demand accuracy, speed, and efficiency.

Write a comment ...